Expeditions with MCUP

Integration and Innovation Challenges in U.S. Navy Logistics

Ira Lewis and Nicholas Dew

21 July 2025

https://doi.org/10.36304/ExpwMCUP.2025.08

PRINTER FRIENDLY PDF

EPUB

AUDIOBOOK

Abstract: Logistics plays a central role in ensuring the lethality and readiness of the U.S. Navy. However, management practices and leadership challenges associated with the peripheral situation of logistics in the Navy make it difficult to exploit information and build knowledge that could lead to improved organizational performance. In both acquisition and sustainment, the Navy needs to better exploit logistics knowledge and significantly modernize the information systems that support the creation of that knowledge. Given that logistics processes cross internal and external boundaries as they support operational effectiveness, the Navy should also consider a greater degree of integration between operations and logistics.

Keywords: defense innovation, sustainment, acquisition, process integration, strategy

Introduction

Battles are decided by the quartermasters before the first shot is fired.

~ Field Marshal Erwin Rommel[1]

The U.S. Navy’s management practices and leadership have lagged in ensuring that an effective system of logistics can adequately support operational effectiveness, particularly given the challenges of both new and legacy weapon and support systems paired with an increased pace of operations. In this article, the authors suggest that the primacy of logistics to military operations requires effective integration through both management practices and leadership. Notably, what can be termed the two solitudes of logistics, represented by the acquisition and sustainment functions, need to evolve significantly in the Navy, in the direction of shared purpose and decision making that the other U.S. military Services are currently moving toward.[2]

The other Services are using the challenges of current and anticipated operational environments to strengthen the centrality of logistics in operational planning and doctrine. According to a U.S. Marine Corps publication:

In recent years, we have identified logistics as the “pacing function” for operations. Among the seven warfighting functions, logistics most dictates the tempo of operations and the operational reach of a unit. No other warfighting function more profoundly affects our ability to persist in contested spaces.[3]

For the Navy, a shared understanding of the interrelationship of logistics and operations and better coordination are needed. The division of responsibilities between the Office of the Secretary of the Navy (SECNAV), which has primary responsibility for acquisition, and the Office of the Chief of Naval Operations (OPNAV), which has primary responsibility for logistics and fleet support, is an important consideration.[4] Bruce Stubbs has described this division of responsibilities as “incorrect and artificial.”[5]

For example, contracting with the shipbuilding industry is considered acquisition, which falls under SECNAV. In contrast, ship repair is considered a logistics activity and is overseen by OPNAV. A review by the U.S. Government Accountability Office (GAO) found that the actions of the two organizations were not well coordinated and had led to contradictory efforts. Most repair of surface ships is carried out by private firms, with the Navy’s four in-house shipyards responsible for repairs of aircraft carriers and submarines. In addition, most of the companies that carry out ship repair for the Navy also have shipbuilding contracts, emphasizing the need for a coordinated approach by SECNAV and OPNAV.[6]

Funding by SECNAV for infrastructure improvements at shipyards, meant to stabilize the industrial base in shipbuilding and ship repair, could undermine initiatives by OPNAV to increase competition by encouraging new firms to enter the ship repair sector. This cleavage within the Navy does not extend to all vessels; for example, for the littoral combat ship (LCS), acquisition and sustainment are overseen by SECNAV. The GAO also found that the Navy was “not structured for leadership to gain an understanding of the consequences of decisions intended to affect shipbuilding that could also affect repair, and vice-versa.”[7] SECNAV is undertaking efforts to better integrate responsibilities and decision making for shipbuilding and ship repair.

The shipbuilding challenges are significant and persistent. GAO found that the well-examined, deficient management practices that led to major cost overruns and reduction in the number of ships acquired for the Zumwalt-class destroyer and LCS in the early 2000s had repeated since 2020 with the Constellation-class frigate and landing ship medium.[8] The Navy does not appear to have significantly changed its shipbuilding practices following the challenges with the Zumwalt-class destroyer and LCS, with unfortunate results. To foreshadow one of the major arguments of this article, the GAO has repeatedly called out the importance of knowledge-based practices in its reviews of shipbuilding (and major weapons systems across the Services) since at least 2008–9 and has repeatedly pointed to the relationship between knowledge and the performance of major acquisition programs.[9] The authors will return to this theme in detail.

The Navy’s challenges occur in the context of significant improvements in information technology that have had a major impact on logistics, notably increases in processing power, the speed of communications, and graphics and display capabilities. Hardware is increasingly defined by software, leading to the emergence of the “internet of things” or “cyber-physical systems.” This includes weapons and support systems that are increasingly defined by software and remote control. The ability to easily exchange information about equipment health and inventories of parts and components has led to increased involvement by original equipment manufacturers (OEMs) in all aspects of system support throughout the life cycle. The increased scope of OEM involvement has added a more predictable revenue stream for OEMs that can also serve to offset development costs.

Shortages of government personnel, as well as the increasing complexity of weapons and support systems, have also favored increased OEM or third-party private sector involvement. An additional factor related to the increasing prevalence of software-enabled systems is the need for continual updating, which can lead to a blurring of the distinction between acquisition and sustainment. As has been pointed out, in defense technology “little attention has been paid to the most significant adoption challenge: the lack of computing power and connectivity necessary to support the influx of updates required to take advantage of emerging technologies.”[10] In this context, the Navy must actively plan for a hardware and software technology refresh and insertion, which requires the alignment of incentives, organizations, and processes throughout the lifecycle of systems and components.[11]

One important idea that this preamble highlights is the extent to which the Navy is a very knowledge-intensive enterprise. The Service relies heavily of knowledge resources across all aspects of its activities, as is typical of sophisticated organizations. Therefore, in this article the authors propose a novel analysis of the Navy’s logistics enterprise that emphasizes what might be learned from a knowledge-based view of organizations.[12] The central assertion of this perspective is that knowledge is the most important strategic resource organizations have because knowledge resources are the strongest driver of the competitiveness of organizations.[13]

Knowledge resources therefore matter greatly for military organizations that periodically face the ultimate competitive test of conflict. Knowledge sits at the center of organizations’ competitiveness because it is superior knowledge that, for example, enables an organization to train its people more effectively, to devise operational procedures that beat its adversaries, and to acquire, build, maintain and support better equipment than its rivals can. Furthermore, knowledge resources are known to be enablers of other organizational resources that affect performance, which makes them a multidimensional element in the overall competitive advantage of an organization.[14]

Therefore, in this article, the authors emphasize that a main issue for Navy logistics is to apply management practices and leadership that enable the Navy to “acquire, integrate, retain and motivate knowledge-related resources.”[15] This is a cross-functional challenge because logistics activities, including the acquisition of weapon and support systems, are inherently horizontal processes, involving many organizations throughout the Navy and the U.S. Department of Defense (DOD). Other U.S. military Services, notably the Marine Corps, the Army, and the Air Force, are actively exploring how to better integrate the different logistics functions throughout the life cycle.[16] The Marine Corps is adapting its logistics processes by moving from “a force optimized for supporting sustained operations ashore to a maritime force capable of supporting operations in austere, expeditionary, and littoral environments that are contested across all domains.”[17]

The Navy has challenges in the area of integrated logistics in part because it lacks a Service-wide planning process that effectively sets priorities in a manner that will lead to corresponding allocations of budgets and personnel.[18] For the Navy, the shift toward greater reliance on industry for in-service support also creates challenges for deployed forces. This includes, for example, the physical presence of vendor staff aboard combatant vessels to assist or replace the sailors who operate and maintain systems. This approach is being used, for example, to field uncrewed systems aboard deployed U.S. Navy ships.[19] Additionally, resupply of equipment and parts, as well as the associated transmission of information, by commercial means may not be possible. A knowledge-based analysis would suggest that the Navy’s logistics challenges can ultimately be traced back to management practices and leadership that have yet to sufficiently grasp the centrality of knowledge resources for the performance of Navy logistics, and, by extension, operations.

The article proceeds as follows. The next section sets the scene for what follows by addressing the fundamental issue of contested logistics and Navy doctrine. In section three, the authors focus on the centrality of logistics for naval operations. Section four deals in more detail with operations and logistics and introduces the issue of integrating innovative systems. Section five addresses some of the Navy’s extant models for integrating logistics and operations. Section six shifts to interpreting these Navy logistics issues through the lens of a knowledge-based framework. The final section wraps up the article with practical suggestions for improving the integration of U.S Navy logistics.

Contested Logistics and Navy Doctrine

Shifts in U.S. national policy toward preparing for great power competition (GPC) have led to increased recognition of the need to operate in a “contested logistics environment,” which Congress has defined as “an environment in which the armed forces engage in conflict with an adversary that presents challenges in all domains and directly targets logistics operations, facilities, and activities in the United States, abroad, or in transit from one location to the other.”[20] To operate in such an environment, military forces need to implement planning and management practices that allow for rapid adaptation, such as increased manufacturing or the rerouting of supplies in transit, as necessary due to the impact of enemy action or other unforeseen events.

However, contested logistics is simply a necessary part of military logistics that, in the past few decades without major wars, may have gotten unduly focused on efficiency, cost reduction, and outsourcing, which might be detrimental to supporting large contingency operations.[21] Contested logistics requires a more integrated effort among and between the U.S. military Services and defense agencies. The logistics challenges of GPC, notably in the case of China, are significant:

If the United States fights China in the Western Pacific, the Chinese can fight from “home station.” That advantage drastically reduces their logistics challenges relative to those faced by the United States (though if the United States can transform the conflict into a broader regional fight over control of the sea lines of communication, the challenges faced by the two sides may be comparable). We need to make the logistics triad—transport systems, physical military infrastructure, and digital/cyber infrastructure tying everything together—a top priority in our defense modernization efforts as well.[22]

Also, contested logistics requires greater interagency cooperation (notably with the U.S. Department of State) and with allies and partners due to challenges such as trade/customs barriers, political instability, and technological disruptions.[23] As Zachary S. Hughes explains:

Now, evidence is emerging suggesting that each Service’s individual concept is probably logistically unsustainable. Even worse, each Service concept implicitly transfers risk from the Service to the joint force but without a clear accounting of how all these risks aggregate together. This is even more disturbing because a survey of historical Great Power wars—and a specific study of China’s likely military options—strongly suggests that logistics is likely to be the primary determinant of military success or failure. For dispersed operations to succeed in a contested logistics environment, the U.S. military must address the problem coherently as a joint force. This requires facilitating a culture and organizations that integrate logistics jointly at every level of warfare, while giving logistics pride of place in both force design and campaign planning.[24]

At its core, the concept of contested logistics requires a reduction in demand, due to the possibility of interruptions in the movement of personnel, equipment, and supplies, as well as in communications. In its concept of expeditionary advanced base operations (EABO), the Marine Corps emphasizes minimizing the footprint ashore, using more prepositioning of equipment and supplies, and leveraging host nation or other local sources using flexible forms of contracting.[25] As Hughes explains, “Marine observers have quietly begun to acknowledge that the operational concepts may themselves be logistically infeasible.”[26] That observation points to the fact that the Marines have undertaken a public and broad approach to restructuring doctrine and organizational structure for GPC, and are learning and adapting from it, with open discussion playing an important role.[27]

In contrast to the Marine Corps, it is difficult to discern, at least from open sources, the Navy’s intent for how logistics will evolve to prepare for GPC. Unlike the Army, Air Force, and Marine Corps, Navy doctrinal publications have restricted distribution to government personnel and contractors only. Also, the organization responsible for the development of doctrine, the Navy Warfare Development Center, is a division of an operational command, the U.S. Fleet Forces Command.

In 2022, the Navy announced the concept of distributed maritime operations (DMO) to assist in planning for GPC. A 2024 Navy document explains that DMO:

[D]escribes the fleet tactics that capitalize on the diverse capabilities provided by the Navy and our unique partnership with the Marine Corps. As the reach of missiles gets longer, and lower-cost robotic systems make ship defense costlier, we must put more munitions on more platforms in more places to prevail on a globalized battlefield. [DMO] animates our ecosystem, enabling the levels of distributed warfare and mission command that we need to gain and exploit sea control. As the Navy Warfighting Concept describes Navy operational integration up and out (with the Joint Force, Allies, and partners), [DMO] describes the Navy’s fleet tactics down and in.[28]

With the advent of DMO, there is a case to be made for a Navy approach to warfighting and doctrine development that is like that of the other Services, as suggested by Dmitry Filipoff:

A new warfighting development command could be in the vein of the Army’s four-star Training and Doctrine Command (TRADOC) or the Marine Corps’ three-star Combat Development Command (MCCDC). Such a command should report to the CNO [Chief of Naval Operations] and service leadership, rather than reside within the operational chain of command. Otherwise, longer-term force development imperatives will likely be eclipsed by near-term operational demands. Such a command can help ensure that DMO, or any other service warfighting concept, develops as a cohesive fleet-level approach, rather than a fragmented blend of skillsets that are independently grown by siloed communities.[29]

Given the secondary or subordinate role that support functions such as logistics have traditionally played in the Navy hierarchy, it becomes particularly important under GPC for there to be an integrative approach to the logistics aspects of warfighting, for both force planning and doctrine development.

The Centrality of Logistics in the Navy

Navy leaders have recently highlighted the centrality of logistics to operations. For example, the Commander of the U.S. Indo-Pacific Command (INDOPACOM), Admiral Samuel J. Paparo Jr., has stated that the “Navy should advocate for a larger, more modernized, more capable Combat Logistics Force,” which consists mostly of supply vessels and fuel tankers operated by civil service mariners employed by the Military Sealift Command (MSC).[30] Andrea K. Orlowski, deputy director of engineering at MSC, explains that despite that organization’s critical support role for deployed combatant vessels, the Navy’s fragmented approach has consequences: “Because MSC’s different roles with different agencies and commands are not fully understood, budgetary advocacy and allocation are negatively affected.”[31] An example of the lack of support for logistics is the Navy’s current plan to sideline 17 MSC vessels due to a lack of civil service mariners to crew those ships.[32]

Hughes points out that “succeeding in a conflict with China requires that logisticians gain an increasingly dominant voice in planning and design,” and that in GPC, “logistics is maneuver.”[33] In that vein, Aaron A. Angell suggests that:

Using logistics as maneuver increases the range of flexible deterrence and response options. While combat action and overt military maneuvers with armed weapon systems may have some impact, the posturing of logistics capability in a particular theater may provide an even more grand expression of intent. The deliberate buildup of forces along a border draws attention. However, the presentation of a force can be a hollow demonstration if it is not backed up by a resilient logistics system. If the objective is to prevent war or even a limited military action, then the use of logistics as maneuver can be the appropriate investment to deter potential adversaries.[34]

The Congressional Research Service (CRS) has outlined some challenges with the DMO concept, which is a key Navy initiative for taking on the challenges of GPC. CRS noted concerns that included the extent to which the other Services were consulted during concept development, as well as potential implications for Navy shipbuilding, weapon acquisition programs, and associated industrial bases.[35] Dmitry Filipoff has also expressed some apprehension with the Navy’s siloed approach to warfighting development among the Service’s occupational communities, as well as about the Navy’s capacity for operational learning.[36] Those views were recently echoed by four naval officers writing in Joint Force Quarterly:

As an essential element of maritime strategy, DMO proposes tackling the “tyranny of distance” across the physical and electromagnetic domains through investment in command and control, fires, and sustainment technologies—many of which are either theoretical or still in development. Broad acceptance of these nascent warfighting capabilities can make even the most detailed sustainment planning estimates seem aspirational and, absent historical precedents, risk becoming counterfactual.[37]

In that context, Filipoff also notes that the increase in physical distances contemplated by DMO also requires a focus on unity of effort.[38] Sand D. Miller and Timothy P. Vadala have proposed improved logistics education for unrestricted line (URL) officers such as surface warfare officers, submariners, and aviators and mention that Navy leadership considers the deficiency in logistics knowledge among URL officers to be a “critical force vulnerability.”[39] In addition to the effects of enemy action, the impact of extreme weather on logistics capabilities is a significant consideration for military planners. A series of wargames overseen by Rand for INDOPACOM found that key operating locations such as Guam or Darwin, Australia, to be vulnerable to natural disasters. For example, tropical storms, fires, and extreme heat had the potential to significantly reduce the logistics support to deployed forces.[40]

For the Navy, the implication is that under DMO, logistics factors will need to be well-integrated into operational decision making. Yet, Brent D. Sadler has cautioned that DMO “depends on a robust logistical foundation that could outstrip the Navy’s current capabilities.”[41] In that sense, logistics should emerge as a “pacing function,” with logistics having the same importance to the planning and conduct of operations in the Navy envisaged by the Marine Corps in the EABO concept.[42]

Operational Strategy, Logistics, and the Integration of Innovative Systems

According to Mark Erbel and Christopher Kinsey, the relationship between military operational strategy and logistics is a reciprocal one.[43] Keenan D. Yoho and colleagues add that logistics has the function of providing options to operational commanders to be considered as part of potential courses of action.[44] However, in the U.S. Navy, fragmentation of the logistics function makes playing this central role difficult and exacerbates the relative lack of status held by logisticians relative to the operational commanders and staffs they work with.

The geographic combatant commands, such as INDOPACOM, are responsible for U.S. military operations within their assigned area of responsibility (AOR).[45] Each geographic combatant command includes subordinate Service-level organizations, such as the Navy’s U.S. Pacific Fleet (PACFLT). Both INDOPACOM and PACFLT have logistics staffs, which are primarily concerned with operational sustainment of the forces deployed in the INDOPACOM AOR.

INDOPACOM recently began working with the Defense Innovation Unit (DIU) on the acquisition of products and services to support its mission.[46] In doing so, INDOPACOM is in effect bypassing the established requirements definition process (led by the Joint Chiefs of Staff and the Office of the Secretary of Defense), as well as skirting the acquisition and sustainment organizations of the Services. The purpose of the new, direct arrangements is to meet certain needs of the warfighter more quickly in the INDOPACOM AOR that were perceived as being delayed by the traditional requirements definition, acquisition, and logistics processes.

One particular challenge for INDOPACOM’s Navy elements in working with DIU will be overcoming the independent pursuit of strategic visions by the Navy’s major warfare communities, which are surface warfare, aviation, and undersea warfare.[47] Many of the technologies being developed by nontraditional firms, such as uncrewed vehicles, cross the boundaries between these warfare communities, and the Navy will need to present a more integrated picture to function as a knowledgeable client for DIU and the firms that agency contracts with. Indeed, how SECNAV and OPNAV plan to modify their processes to integrate the products and services acquired by DIU for Navy use will need to be addressed. The INDOPACOM-DIU arrangement has the intent of bringing the warfighter much closer to the acquisition and logistics functions.

In that context, distinguishing between acquisition and sustainment, and limiting participation in these activities to individual warfare communities, has become challenging and of limited relevance in managing modern weapon and support systems. Also, the rapid acquisition of products and services would appear to point to a need for a corresponding integrated logistics process. This is the case, for example, with uncrewed systems, where technological change occurs rapidly and a correspondingly rapid development and fielding cycle is needed.[48] Without a well-integrated logistics process that informs and is informed by operational decision making, the effective adoption of new Navy systems, particularly with respect to sustainment and other aspects of life cycle support, may become more difficult.

Some Extant Models for Integrating Logistics with Operations

Despite the efforts at Joint capability integration spawned by the Goldwater-Nichols Department of Defense Reorganization Act of 1986, each Armed Service competes for its share of defense spending, particularly with respect to acquisition of new systems.[49] Under that scenario, operational capabilities tend to take precedence over mundane requirements such as transportation or resupply. The fact that many of these support functions are provided by one Service for the benefit of the others further exacerbates the problem.

The significant challenges of logistically supporting dispersed forces in, for example, the Western Pacific, create a situation where in some cases funding for new weapons systems and platforms must be traded off against expenditures such as airlift aircraft or supply warehouses (and their contents). Currently, there is no effective way for the DOD to deal with this issue. A further challenge is that the traditional divisions of acquisition logistics vs. sustainment logistics, or intratheater transportation vs. strategic (or intertheater) transportation, may not reflect the actual logistics decision-making process needed to support dispersed forces.

Accordingly, there is a need for clear direction on responsibilities for intratheater movement and Joint logistics in INDOPACOM, which currently appears to default to the Army without any formal assignment of that responsibility.[50] At the Service level, there are also contrasts. The Marine Corps is expanding the role of deployed contracting officers as part of EABO implementation.[51] Yet the Navy, in the wake of the Fat Leonard scandal, has significantly restricted the contracting authority of deployed supply officers, making operational support more difficult even under current “peacetime” conditions.[52]

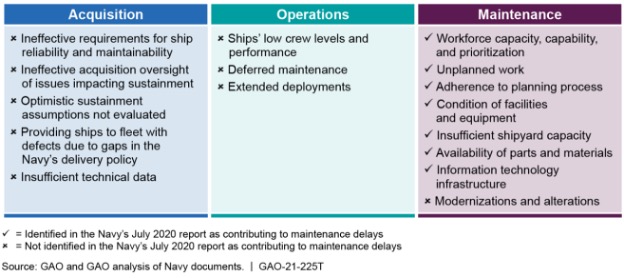

Figure 1. Considerations related to acquisition, operations, and maintenance in the littoral combat ship program

Source: Navy and Marine Corps: Rebuilding Ship, Submarine, and Aviation Readiness Will Require Time and Sustained Management Attention (Washington, DC: Government Accountability Office, 2020), 7.

Figure 1, taken from a GAO report on the LCS, serves as an illustration of the Navy’s challenges in integrating the acquisition and sustainment functions while maintaining a central goal of operational availability. For the purposes of this discussion, “maintenance” can be considered the equivalent of sustainment or in-service logistics support. The challenge for the Navy is to ensure that it broadly puts the knowledge resources in place to effectively address the three categories of factors shown in figure 1, bearing in mind that successive GAO reports have repeatedly highlighted knowledge deficits that need to be addressed.[53] Notably, there is also a need for the Navy to consider sustainment costs earlier in the acquisition process, which would also help with the its operational readiness goals:

It is vitally important to deliver the warfighter the key performance parameters they desire; however, a product that delivers warfighting capability with increasing operating and maintenance costs becomes unaffordable, not solely from those direct costs but from the costs of incremental modernization performed to overcome obsolescence or other maintenance and logistics issues that cause pain for the warfighter. In this era of flat and slightly declining budgets it is critical to make acquisition decisions that consider the long-term affordability, and therefore, viability of fielded systems. The Navy cannot continue to field new ships without correcting this behavior.[54]

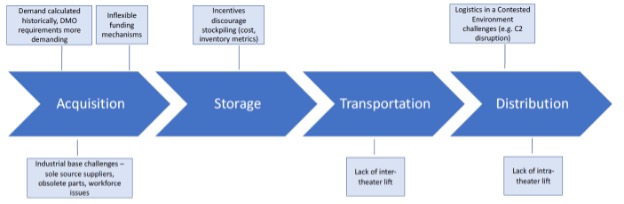

Figure 2. Challenges across the Navy supply chain

Source: Joslyn Fleming et al., Naval Logistics in Contested Environments: Examination of Stockpiles and Industrial Base Issues (Santa Monica, CA: Rand, 2024), 43, https://doi.org/10.7249/RRA1921-1.

Figure 2, from a Rand report by Joslyn Fleming and colleagues, provides a similar overview of the broad Navy supply chain to that of figure 1. Figure 2 incorporates additional considerations throughout the supply chain resulting from logistics in a contested environment, including material shortages and lack of intertheater transportation.[55]

DOD direction already provides for an integrated view of the entire life cycle of weapons and other systems, from conception through disposal. Program managers (PMs) in DOD components are required to implement “effective life cycle management” and are responsible for:

[A]chieving program life-cycle management objectives throughout the program life cycle. Planning for operations and support will begin at program inception, and supportability requirements will be balanced with other requirements that impact program cost, schedule, and performance. Performance based life-cycle product support implements life-cycle system management.[56]

DOD policy also assigns specific responsibilities to a product support manager (PSM), who is responsible to the PM for the following activities:

Product support is critical to achieving and sustaining warfighter readiness and lethality and must begin at program inception to ensure effective and affordable readiness outcomes. Product support management is the organization and coordination of life cycle activities, products, processes, and data required to achieve defined program supportability cost, schedule, and performance objectives.[57]

In the above context, PSMs have a supply chain management role, as part of which they should monitor and manage risks related to operational factors such as contested logistics.[58] These risks are a significant concern for the Navy, with the material condition of amphibious vessels being the subject of a recent GAO report:

As of March 2024, half of the amphibious fleet is in poor condition and these ships are not on track to meet their expected service lives. GAO identified factors that contributed to the fleet’s poor condition and reduced its availability for Marine Corps’ operations and training. For example, the Navy faces challenges with spare parts, reliability of ship systems, and canceled maintenance.[59]

The Navy should make a conscious effort to overcome its integration challenges in logistics, which will be discussed in the next section.

Interpreting the Navy’s Logistics Challenges through a Knowledge-based Framework

The primacy of logistics to military operations means that the Navy needs to take great care to effectively integrate its logistics processes with its operational needs. It is currently the case that many shortfalls and gaps exist between the level of integration that is desirable compared to what is currently being achieved. How might this situation be improved on?

One approach that is advocated in this article is to start by recognizing the knowledge- intensive nature of naval logistics. The Navy relies heavily of knowledge resources across all aspects of its enterprise, no less in logistics than in any other part of its broad sweep of activities. The authors’ argument is that the Navy’s management practices and leadership need to pay more attention to knowledge as the critical resources that provides the backbone to the competitiveness of its elements and the glue to ensure effective integration of functions (e.g. logistics with operations).

First, it is useful to briefly take a step back to reflect on what is known more broadly about organizational performance. It is well understood in organizational research that knowledge resources are by far the most important drivers of the competitiveness of an organization. Key arguments for why this is the case have been known for more than three decades, and empirical research showing the extent of the relationships between knowledge resources and organizational performance are by now beyond any doubt.[60] The bottom line of these results is that knowledge resources are the only major category of resources that are related to all major measures of organizational performance, and they have a much larger relationship to performance than other resources (examples of “other” resources are intangible resources, tangible resources, and relational resources).

Of course, Navy logisticians have many advantaged resources at their disposal, with tangible physical resources most easily coming to mind. More broadly, the Navy has an important collection of competitively advantaged tangible resources, such as best-in-class submarines, the largest and most sophisticated aircraft carriers, and extensive physical infrastructure. However, research indicates that knowledge resources are not only the most important resources driving organizational competitiveness but also critical enablers of readily identifiable tangible resources. For the Navy, a classic example is the effectiveness of a weapons systems (a tangible resource) depends very significantly on the skills of the operators employing it (the relevant knowledge resource).

Knowledge resources that are considered strategic can be categorized into four main groups. Two groups address explicit knowledge resources. The first is knowledge management systems such as directives, policies, and procedures that formalize, store, and distribute organizational knowledge. An example is the Navy’s maintenance processes. The Navy’s maintenance support relies on directives, technical information, and guidance that embodies the knowledge of many specialists, some of whom work for the Navy and others of whom are the Navy’s contractors. Also included in this category are other types of formal knowledge developed through research and development, knowledge contained in patents and copyrights, formalized standard operating procedures, and formalized tradecraft.

A second group of knowledge resources is information systems, which have rapidly become a core organizational resource. The basic idea is that organizational performance depends on how effective an organization is at using information technology to support its key activities.[61] Earlier in this article, the authors noted that the capabilities of weapons and support systems are increasingly defined by software. A great deal of organizational knowledge is embedded in an organization’s bespoke software systems.

A third group of knowledge resources are tacit, which is knowledge embedded in individuals and teams that cannot easily be articulated, codified, or shared. Sailors typically acquire tacit knowledge by on-the-job learning. This knowledge may not be directly observable but is instead embedded in the human capital of an organization’s workforce, which include the skills, knowledge, and experience possessed by individuals. In the absence of direct measures, years of education and professional experience are often used to measure tacit knowledge. Like all the U.S. military Services, the Navy invests heavily in training, educating, and retaining its people. The team aspect of these knowledge resources is related to the concept of human capital externalities, which are the benefits of an individual’s human capital that accrue to others beyond the individual themselves. The Navy puts extensive emphasis on teams training and working together the same way that they will fight together to build valuable tacit knowledge resources.

A fourth group of knowledge resources is also tacit, which is organizational learning. This is typically embedded in routines and procedural know-how that is acquired through collective practice and experience. In naval logistics, exercises provide a primary way that this type of knowledge is practiced, and actual operations provide experience.

The knowledge-based framework would suggest that improving the integration of Navy logistics with operational needs will depend on the Navy bringing more extensive knowledge resources to bear on this issue.[62] While there are many aspects to this issue, the underlying point is for the Navy to apply management practices and leadership that drive the acquisition, integration, retention, and motivation of the requisite knowledge-based resources needed to address the specific integration challenges the Navy faces.

The Navy could start by addressing the aforementioned deficits in the logistics education of URL officers such surface warfare officers and aviators. Given that this deficiency has already been identified as a “critical force vulnerability,” it behooves the Navy to invest in training, education, and experiences that would broaden the knowledge base of URL officers in ways that enhance the Navy’s capability to integrate logistics with operations.[63] Similarly, the Navy could more systematically send URL officers for graduate education in acquisition (program management and contract management) prior to assigning these officers as program managers of major acquisition projects, which is the practice of the other military Services.

Retention and motivation of the Navy’s uniformed and civilian workforce are other key aspects of the people category of knowledge resources. In recent years multiple reports have highlighted critical skills gaps in the Navy workforce, such as critical skills in shipbuilding and maintenance activities (see, for example, figure 1 for examples of deferred maintenance and modernization and alterations for the LCS program). Despite the application of Navy management and leadership to these issues, fundamental shortfalls remain that the Navy could address under the umbrella framework of knowledge resources relating to competitive performance.[64]

Next, the Navy could make management and leadership investments in addressing the acquisition and integration of its software systems. As has been highlighted, software is an increasingly critical knowledge resource in naval logistics as well as in naval operations in general. While the Navy undoubtedly possesses some advanced software-enabled capabilities, it, like the rest of the DOD, also has obsolescent software systems in its overall portfolio. The result is a lumpy software landscape in which innovative capabilities reside alongside some very outdated software artifacts that are a drag on organizational performance.

The DOD recently announced an effort to modernize its software acquisition practices, with a focus on increasing the number of nontraditional vendors and incorporating leading software development practices.[65] Importantly, the Navy has not grasped the opportunity cost in operational effectiveness of not investing in top-of-the-line software capabilities and in making these capabilities continually available to sailors when underway. In this regard, the deployment of commercial satellite internet capabilities (e.g. Starlink) on Navy surface vessels is a vital action, as this enabling technology allows access to a wide range of knowledge resources that improve operational effectiveness. Therefore, the Navy should make deploying this technology to the rest of the surface fleet a top priority. As has been alluded to, in some cases the Navy is overreliant on the software capabilities of OEMs for life-cycle systems support and lacks in-house organic capabilities to continually update critical software systems; both issues warrant attention.[66]

Organizational learning involves a type of knowledge resources that are tacit and often embedded in routines and procedural know-how.[67] In the course of this article, the authors have repeatedly highlighted the challenges the Navy faces in integrating its activities between its own organizational elements (working under the banner of the Navy’s DMO concept), as well as with related naval elements (e.g., the Marine Corps, working under the EABO concept), and with the other military Services (e.g., the Army, which is responsible for Joint logistics in INDOPACOM).[68] While these integration challenges clearly demand to be formally worked out and embodied in the relevant directives, they also need to be worked out in practice. That can only happen through realistic training exercises in which routines and processes can be practiced and battle-tested. Research on the knowledge-based framework emphasizes the complexity of these organizational processes and the distributed nature of the participants, hence that knowledge resources of this type are built through patient investment in opportunities to rehearse and practice.

Finally, this article has highlighted several examples in which improving the integration of Navy logistics requires investments in knowledge management systems such as doctrine and procedures. Formal systems that develop, store, and distribute organizational knowledge remain an important part of how complex organizations such as the Navy function. One simple example is the Navy’s rules governing the activities of contracting officers, which not only differ markedly from the Marine Corps’ approach but substantially impede support for deployed naval units.[69] Here, and with many other examples, the Navy incurs substantial opportunity costs to its logistics enterprise by applying directives that are not geared to the overall competitive performance of the organization in terms of lethality and readiness. The important takeaway from this and other examples is the role of flexibility and adaptation in updating critical knowledge resources in ways that maximize an organization’s performance of its most critical tasks while controlling risk areas.

Conclusion

In the U.S. Armed Services, logistics is defined as “movement and maintenance of forces.”[70] Logistics is inherently a process that crosses internal and external boundaries, involving multiple chains of command within the DOD in collaboration with other federal agencies, the private sector, and allied governments. The U.S. Navy, as an organization focused on lethality and readiness, emphasizes the performance of operational units involving ships, aircraft, and weapons systems, operating under well-defined chains of command, as exemplified by the concept of “command at sea.”[71]

Logistics processes, whether for initial acquisition of a piece of equipment or in support of deployed forces, are a burden on operational commanders and a critical enabler of their performance. Logistics also requires collaboration and compromise, particularly by operational commanders who may need to subordinate their immediate interests to achieve broader or longer-term goals. The dispersed nature of naval operations, combined with internal distinctions such as between URL officers and those in support roles, or between SECNAV and OPNAV, makes leveraging and integrating knowledge for innovation more difficult. The Navy is inherently a large and complex organization with necessary distinctions among organizational components and occupational communities. However, diverse logistics challenges from ship maintenance to software acquisition demonstrate the need for more effective management practices and more focused leadership that integrates knowledge across boundaries.

During the past decade, the Navy has undertaken a number of logistics-related process improvement programs such as “Get Real Get Better.”[72] These initiatives have been successful in reducing bottlenecks and, for example, improving the operational availability of aircraft. Yet, they mostly depend on contractors, raising concerns about the knowledge generated being diffused and retained throughout the Navy’s military and civilian workforce. The need for efficient and modern information systems for support activities such as logistics, combined with the increasing embeddedness of software in weapons systems, reinforces the importance of genuine collaboration and compromise in both planning and operations.

A more integrated approach to logistics in the Navy would also face significant challenges. Operational commanders and their staffs must focus on the short-term mission. It is also difficult to justify diverting funds from immediate operational priorities to support longer-term readiness. In that context, the Navy might benefit from reviewing and adapting relevant innovations from the other U.S. Services and allied navies.

The authors do not believe that achieving these improvements to the centrality of logistics within the Navy will require reorganizations. Rather, as an institution, the Navy needs to better exploit the knowledge it has and significantly modernize the information systems that support the creation of knowledge. In acquisition and sustainment, the Navy needs to better exploit logistics knowledge and significantly modernize the information systems that support the creation of that knowledge. Given that logistics processes cross internal and external boundaries as they support operational effectiveness, the Navy should also consider a greater degree of openness in the evolution of warfighting doctrine and the role logistics plays in operational performance.

Endnotes

[1] Quoted in Spc Mike MacLeod, USA, “On the Ground with Advise and Assist Commander,” Defense Visual Information Distribution Service, 10 November 2009.

[2] Timothy B. Beger, “Developing a Concept of Employment for Marine Corps ULS-A from a DOTMLPF-P Perspective” (thesis, Naval Postgraduate School, Monterey, CA, 2024); and Cortni S. Thrasher and Blayne M. Martz, “Contested Logistics Engineering of Shinmaywa US-2 in Support of DMO” (capstone applied project report, Naval Postgraduate School, Monterey, CA, 2024).

[3] Gen David H. Berger, Installations and Logistics 2030 (Washington, DC: Headquarters Marine Corps, 2023), 1, emphasis added.

[4] As explained by the Congressional Research Service, “The Department of the Navy (DON) is a single military department that includes two military services—the Navy and the Marine Corps. As such, DON has a single civilian leader, the Secretary of the Navy, and two four-star military service chiefs—an admiral whose title is the Chief of Naval Operations (CNO), and a general whose title is the Commandant of the Marine Corps. Although the title ‘Secretary of the Navy’ includes only the term ‘Navy,’ the secretary serves as the civilian leader for both the Navy and Marine Corps.” Ronald O’Rourke, Defense Primer: Department of the Navy (Washington, DC: Congressional Research Service, 2025). This report also provides an explanation of the organizational structure of the DON.

[5] Bruce Stubbs, “I Blame the Navy’s Strategic Woes on the Chiefs of Naval Operations,” War on the Rocks, 13 November 2024.

[6] Shipbuilding and Repair: Navy Needs a Strategic Approach for Private Sector Industrial Base Investments (Washington, DC: Government Accountability Office, 2025).

[7] Shipbuilding and Repair, 56.

[8] James S. Talbert Jr., “How Acquisition Decisions Impacted Fleet Readiness in the LCS Platform” (capstone applied project report, Naval Postgraduate School, Monterey, CA, 2024); and Navy Shipbuilding: Enduring Challenges Call for Systemic Change (Washington, DC: Government Accountability Office, 2025).

[9] See, for example, Defense Acquisitions: A Knowledge-based Funding Approach Could Improve Major Weapon System Program Outcomes (Washington, DC: Government Accountability Office, 2008); Best Practices: High Levels of Knowledge at Key Points Differentiate Commercial Shipbuilding from Navy Shipbuilding (Washington, DC: Government Accountability Office, 2009); Weapon Systems Annual Assessment: Limited Use of Knowledge-based Practices Continues to Undercut DOD’s Investments (Washington, DC: Government Accountability Office, 2019); and DOD Acquisition Reform: Increased Focus on Knowledge Needed to Achieve Intended Performance and Innovation Outcomes (Washington, DC: Government Accountability Office, 2021).

[10] Dale Swartz, Ryan Brukardt, and Karl Hujsak, “Creating a Modernized Defense Technology Frontier,” McKinsey and Company, 12 February 2025. See also Navy Readiness: Actions Needed to Improve Support for Sailor-led Maintenance (Washington, DC: Government Accountability Office, 2024).

[11] Jonathan P. Wong et al., Improving Defense Acquisition: Insights from Three Decades of Rand Research (Santa Monica, CA: Rand, 2022), https://doi.org/10.7249/RRA1670-1.

[12] Robert M. Grant, “Toward a Knowledge-based Theory of the Firm,” Strategic Management Journal 17, no. S2 (Winter 1996): 109–22, https://doi.org/10.1002/smj.4250171110.

[13] Donald D. Bergh et al., “Is Knowledge Really the Most Important Strategic Resource?: A Meta-analytic Review,” Strategic Management Journal 46, no. 1 (January 2025): 3–18, https://doi.org/10.1002/smj.3645.

[14] J. C. Spender and Robert M. Grant, “Knowledge and the Firm: Overview,” Strategic Management Journal 17, no. 2 (Winter 1996): 5–9, https://doi.org/10.1002/smj.4250171103.

[15] Bergh et al., “Is Knowledge Really the Most Important Strategic Resource?,” 4.

[16] LtCol Michelle P. Santayana, USA, and Capt Stephen Gowen, “Strategic Enablers: Supporting LSCO in a Contested Environment,” Army Sustainment 55, no. 1 (Winter 2024): 66–71; and James A. Leftwich et al., Exploring Options to Improve Supply Chain Operations: A Review of Current Approaches and New Opportunities in Demand Forecasting, Robotic Process Automation, and Cyber Integrity (Santa Monica, CA: Rand, 2024), https://doi.org/10.7249/RRA1734-1.

[17] Installations and Logistics 2030, 3. See also Steven A. Yeadon, “Recommendations for Improving the U.S. Marine Corps’ Force Design,” Expeditions with MCUP, 27 January 2025, https://doi.org/10.36304/ExpwMCUP.2025.03.

[18] Stubbs, “I Blame the Navy’s Strategic Woes on the Chiefs of Naval Operations.”

[19] “U.S. Navy Awards Leidos $248 Million Contract to Provide Autonomous Systems Design and Engineering,” Leidos, 17 October 2024.

[20] Michael J. Mazarr, Understanding Competition: Great Power Rivalry in a Changing International Order—Concepts and Theories (Santa Monica, CA: Rand, 2022), https://doi.org/10.7249/PEA1404-1; and “Contested Logistics Environment,” in 10 U.S.C. § 2926(h) (2021). See also Maj Jon Michael King, USA, “Contested Logistics Environment Defined,” Army Sustainment 55, no. 1 (Winter 2024): 46–49.

[21] LtCol Amos C. Fox, USA, “Contested Logistics: A Primer,” Association of the United States Army, 2 February 2024.

[22] Marcos A. Melendez III, Michael E. O’Hanlon, and Jason Wolff, “America Can’t Afford to Ignore the Logistics Triad,” Brookings Institution, July 2023.

[23] Santayana and Gowen, “Strategic Enablers”; Wong et al., Improving Defense Acquisition; and Harry Halem, “Distributed Maritime Operations, Logistics, Industry, and American Strategy in Asia,” Military Strategy Magazine 10, no. 2 (Spring 2025).

[24] Zachary S. Hughes, “Giving Our ‘Paper Tiger’ Real Teeth: Fixing the U.S. Military’s Plans for Contested Logistics against China,” Joint Force Quarterly 115 (4th Quarter 2024): 29, emphasis in original.

[25] Tentative Manual for Expeditionary Advanced Base Operations, 2d ed. (Washington, DC: Headquarters Marine Corps, 2023).

[26] Hughes, “Giving Our ‘Paper Tiger’ Real Teeth,” 33.

[27] Robert Work, “Marine Force Design: Changes Overdue Despite Critics’ Claims,” Texas National Security Review 6, no. 3 (Summer 2023): 81–98, http://dx.doi.org/10.26153/tsw/47411; and Albin Aronsson, China First for the U.S. Marine Corps: Fast-paced Adaptation and Reform (Kista: Swedish Defense Research Agency, 2025).

[28] Adm Lisa M. Franchetti, USN, Chief of Naval Operations Navigation Plan for America’s Warfighting Navy (Washington, DC: Department of the Navy, 2024), 14.

[29] Dmitry Filipoff, Distributed Maritime Operations: Solving What Problems and Seizing Which Opportunities? (Washington, DC: Atlantic Council, 2024), 17.

[30] Jan Tegler, “Navy Depends on Contractor for Heavy Lift Vertical Deliveries,” National Defense, 8 January 2025; and Halem, “Distributed Maritime Operations, Logistics, Industry, and American Strategy in Asia.”

[31] Andrea K. Orlowski, “MSC Could Use a Balisle Report of Its Own,” U.S. Naval Institute Proceedings 151, no. 1 (January 2025).

[32] Sam LaGrone, “Navy Could Sideline 17 Support Ships Due to Manpower Issues,” USNI News, 22 August 2024.

[33] Hughes, “Giving Our ‘Paper Tiger’ Real Teeth,” 36–37.

[34] Col Aaron A. Angell, “Logistics as Maneuver: Strategic Messaging across the Competition Spectrum,” Marine Corps Gazette 108, no. 3 (March 2022): 22.

[35] Ronald O’Rourke, Defense Primer: Navy Distributed Maritime Operations (DMO) Concept (Washington, DC: Congressional Research Service, 2025).

[36] Filipoff, Distributed Maritime Operations.

[37] Debra D. Buckland-Coffey et al., “Bullets, Bandages, and Fairy Dust: Improving DMO Health Services Support with Wargaming,” Joint Force Quarterly 116 (1st Quarter 2025): 102.

[38] Filipoff, Distributed Maritime Operations.

[39] Sand D. Miller and Timothy P. Vadala, “Improving Unrestricted Line Officer Community Corps Logistics Knowledge: Key Concepts and Processes” (MBA professional project, Naval Postgraduate School, Monterey, CA, 2022).

[40] Bryan Rooney et al., Ho’okele Mua II, a Wargame on Climate Change and Operational Risk in INDOPACOM (Santa Monica, CA: Rand, 2025), https://doi.org/10.7249/RRA470-8.

[41] Brent D. Sadler, “Navigation Plans Need Leadership and Resources to Get the Navy Truly Underway” Center for International Maritime Security, 29 October 2024.

[42] Installations and Logistics 2030.

[43] Mark Erbel and Christopher Kinsey, “Think Again—Supplying War: Reappraising Military Logistics and Its Centrality to Strategy and War, Journal of Strategic Studies 41, no. 4 (2018): 519–44, https://doi.org/10.1080/01402390.2015.1104669.

[44] Keenan D. Yoho, Sebastiaan Rietjens, and Peter Tatham, “Defence Logistics: An Important Research Field in Need of Researchers,” International Journal of Physical Distribution and Logistics Management 43, no. 2 (2013): 80–96, https://doi.org/10.1108/IJPDLM-03-2012-0079.

[45] Caitlin Campbell, Cameron M. Keys, and Luke A. Nicastro, U.S. Indo-Pacific Command (INDOPACOM) (Washington, DC: Congressional Research Service, 2024).

[46] Brandi Vincent, “DIU, Indo-Pacific Command Leaders Connect in Hawaii on Replicator,” Defense Scoop, 2 August 2024.

[47] Stubbs, “I Blame the Navy’s Strategic Woes on the Chiefs of Naval Operations.”

[48] Maj Dennis A. Vinett, USA, “Prioritizing Maintenance Restructuring and Resourcing for Autonomous Systems,” Military Review, 105, no. 2 (March–April 2025): 32–41; and Defense Innovation Board, A Pathway to Scaling Uncrewed Weapon Systems (Washington, DC: Department of Defense, 2025).

[49] Goldwater–Nichols Department of Defense Reorganization Act of 1986, Pub. L. 99-433, 100 Stat. 992 (1986); and Wong et al., Improving Defense Acquisition.

[50] Hughes, “Giving Our ‘Paper Tiger’ Real Teeth”; Carmelia Scott-Skillern and Peter Singer, “The Forgotten Part of the Contest: Army Logistics in the Pacific,” War on the Rocks, 29 April 2024; and Michael J. Mazarr et al., Sustaining U.S. Army Operations in the Indo-Pacific (Santa Monica, CA: Rand, 2025), https://doi.org/10.7249/RRA2434-3.

[51] Maj Daniel Katzman, “Sustaining Stand-in Forces: Evaluating the Logistical Supportability for Expeditionary Advanced Base Operations,” Marine Corps Gazette 108, no. 3 (March 2022): 14–19; and Kendal T. Good and Joel A. Stark, “Evaluation and Application of the Field Ordering Officer and Pay Agent Program within the Marine Corps Expeditionary Advanced Base Operations Concept” (thesis, Naval Postgraduate School, Monterey, CA, 2024).

[52] Cdr Grant Bryan, USN, and LCdr Matt Hipple, USN, “Fat Leonard Still Weighs on WestPac Logistics,” U.S. Naval Institute Proceedings 150, no. 11 (November 2024). The Fat Leonard case involved corruption by U.S. Navy personnel in Southeast Asia. Malaysian defense contractor Leonard Glenn Francis bribed officers and civilian employees with cash, luxury goods, and entertainment. In return, Francis received lucrative contracts for providing shore support services to visiting U.S. Navy ships. For more information on the Fat Leonard scandal, see Craig Whitlock, Fat Leonard: How One Man Bribed, Bilked, and Seduced the U.S. Navy (New York: Simon & Schuster, 2024); and “Leonard Glenn Francis Sentenced to 15 Years in Prison for Massive Bribery, Fraud and Disappearance,” U.S. Department of Justice, 5 November 2024.

[53] See, for example, Weapon Systems Annual Assessment: Knowledge Gaps Pose Risks to Sustaining Recent Positive Trends (Washington, DC: Government Accountability Office, 2018); and DOD Acquisition Reform; and Navy Shipbuilding.

[54] Nigel C. Thijs and Mia Korngruen, “Reducing DON Total Ownership Cost: Why Recent Reform Initiatives Will Lower Sustainment Costs and Increase Affordability” (Joint applied project report, Naval Postgraduate School, Monterey, CA, 2021), 27–28. See also Franchetti, Chief of Naval Operations Navigation Plan for America’s Warfighting Navy.

[55] Emily Pesicka, “The Strategic Consequences of Deferred Maintenance: Challenges to the Resilience of U.S. Sea Power,” Small Wars Journal, 25 June 2025.

[56] The Defense Acquisition System, Department of Defense Directive 5000.01, change 1 (Washington, DC: Department of Defense, 2022), 7.

[57] Product Support Management for the Adaptive Acquisition Framework, Department of Defense Instruction 5000.91 (Washington, DC: Department of Defense, 2021), 11.

[58] Project Support Manager Guidebook (Washington, DC: Department of Defense, 2022), 25.

[59] Amphibious Warfare Fleet: Navy Needs to Complete Key Efforts to Better Ensure Ships Are Available for Marines (Washington, DC: Government Accountability Office, 2024).

[60] Bergh et al., “Is Knowledge Really the Most Important Strategic Resource?”

[61] T. Ravichandran and Chalermsak Lertwongsatien, “Effect of Information Systems Resources and Capabilities on Firm Performance: A Resource-Based Perspective,” Journal of Management Information Systems 21, no. 4 (2005): 237–76, https://doi.org/10.1080/07421222.2005.11045820; and Michael Wade and John Hulland, “Review: The Resource-based View and Information Systems Research: Review, Extension, and Suggestions for Future Research,” MIS Quarterly 28, no. 1 (March 2004): 107–42, https://doi.org/10.2307/25148626.

[62] Mark E. Nissen and Simona L. Tick, “Evaluation of Leadership Traits for Future Warfare” (research paper, Naval Postgraduate School, Monterey, CA, 2021).

[63] Miller and Vadala, “Improving Unrestricted Line Officer Community Corps Logistics Knowledge.”

[65] C. Todd Lopez and Maj Wes Shinego, USA, “Modern Software Acquisition to Speed Delivery, Boost Warfighter Lethality,” DOD News, 10 March 2025; and Leading Practices: Iterative Cycles Enable Rapid Delivery of Complex, Innovative Products (Washington, DC: Government Accountability Office, 2023).

[66] Erik Schuh, “DOGE’s Real Challenge in the Pentagon Isn’t Slashing the Workforce, It’s Boosting Productivity,” War on the Rocks, 25 March 2025; and Swartz, Brukardt, and Hujsak, “Creating a Modernized Defense Technology Frontier.”

[67] Daniel G. Lee, “Tolerated Organizational Forgetting in the U.S. Air Force: A Case Study Analysis of Knowledge Loss among Government Civilian Employees” (dissertation, Colorado State University, Fort Collins, CO, 2024).

[68] Hughes, “Giving Our ‘Paper Tiger’ Real Teeth”; and Scott-Skillern and Singer, “The Forgotten Part of the Contest.”

[69] Bryan and Hipple, “Fat Leonard Still Weighs on WestPac Logistics.”

[70] Logistics, Marine Corps Doctrinal Publication 4 (Washington, DC: Headquarters Marine Corps, 2023).

[71] Ens Olivia Morrell, USN, “Bringing Back Sea Power from the Deckplate on up,” Center for International Maritime Security, 11 September 2018.

[72] “Get Real Get Better in Action,” Navy.mil, accessed 17 July 2025; and Maghann Meyers, “Can Navy Warships Follow Aviators’ Path to 80%-deployable Rates?,” Defense One, 7 April 2025.