Expeditions with MCUP

Logistics Gray Swan

History Mocks U.S. Readiness

Patrick O’Brien, PhD; Chip E. Miller, PhD; George Duchak, PhD; Col Brian Cook, USA (Ret); Col Jay Miseli, USA (Ret); and Col John Flanagan, USMC (Ret)

18 July 2025

https://doi.org/10.36304/ExpwMCUP.2025.07

PRINTER FRIENDLY PDF

EPUB

AUDIOBOOK

Abstract: U.S. history reveals a consistent pattern: after major conflicts, the nation embraces postwar optimism and seeks a “peace dividend” through reduced defense spending. This cycle pits congressional focus on domestic priorities against military leaders advocating for continued defense investment—a tension that often leaves the country unprepared for emerging threats. Historical precedents illustrate this dynamic. During World War I, Germany’s unrestricted submarine warfare nearly severed British supply lines—a “gray swan” event that caught Allied forces off guard. Yet, postwar naval commanders, focused on refitting German battleships, failed to anticipate the next war’s character. Similarly, before World War II, U.S. Army brigadier general William L. “Billy” Mitchell publicly embarrassed the U.S. Navy by demonstrating that aircraft could sink battleships, forcing urgent development of carrier-based aviation and new naval tactics. In addition, after the United States won the Cold War against the Soviet Union in 1991, the pattern continued, and military spending was again reduced in anticipation of a “peace dividend.” Today’s conflicts represent another gray swan moment. Russia invaded Ukraine in February 2022, and Hamas conducted surprise attacks against Israel in October 2023, with this second conflict later expanding regionally. These twin conflicts have exposed gaps in the ability of the United States to sustain multiple allies simultaneously with essential warfighting supplies. These recent challenges reveal that the U.S. Defense Industrial Base (DIB), the U.S. Department of Defense, and national logistics capabilities lag behind the demands of modern warfare, making it difficult for companies to sustain capacity and maintain institutional memory.[1] Recent White House executive orders address the scale of DIB deficiencies. This article examines specific logistics challenges and proposes actionable improvements to ensure that the United States can deter—and, if necessary, win—future wars.

Keywords: logistics, munitions, missiles, drones, defense industrial base, gray swans

Introduction

A gray swan event is a known, possible event that is considered to have a low probability of occurrence and/or a low detrimental impact should it occur. In the realm of U.S. defense, such an event might be a multifront, multidomain, high-technology war embroiling the United States. The authors posit: Is the United States prepared to fight, sustain, and win such a conflict? Furthermore, is the U.S. Defense Industrial Base (DIB) capable of inventing, manufacturing, and delivering adequate amounts of munitions, ordnance, and other materiel required so that the United States can effectively deter—and, if needed, win—such a conflict?

After researching this question, the authors believe that it is increasingly evident that the United States cannot logistically sustain such a set of conflicts unless key improvements occur across the U.S. Department of Defense (DOD) and the DIB.[2] U.S. indirect materiel involvement and intelligence support in the current Russo-Ukrainian War and Israel’s multifront conflict with Iran’s proxies—Hamas, Hezbollah, and Houthis—have highlighted strain points in basic logistics—especially munitions, drones, and missiles—for the United States’ readiness to win future wars of its own.

The combined demands of these conflicts exposed serious shortcomings in the ability of the United States to efficiently supply critical weapons systems and munitions of all types to allies while concurrently maintaining stockpiles for its own military needs.[3] Given the significant amount of technological change and innovation globally, the United States appears to be once again imagining the next set of conflicts with an unrealistic type of logistics posture and with unfavorable cost imbalances. Even in conflicts that are not involving the United States directly in war, the pace of technological innovation and adoption by adversaries has strained traditional U.S. and allied manufacturing approaches. These potential future conflicts highlight the necessity of technological supremacy, manufacturing capacity, and industrial might to form a credible deterrent to protect the vital interests of the United States along with credible warfighting concepts. The three examples of manufacturing challenges that follow highlight the need for immediate solutions for problems in the DIB to ensure national security.

Assumptions

World events have been turbulent during the past decade, with the formation of new coalitions, new actors on the world stage, and even more disruptive technology. Given these changes, a constant state of chaos will likely be the normal state of affairs in the future. The recent COVID-19 pandemic’s disruption of global supply networks was a harbinger of future chaos caused by a single event. In addition, the rapid, ever-increasing speed of technology affecting warfare is certain to impact the nature and characterization of future conflict. Unanticipated natural events such as COVID-19, or planned events that disrupt supply chains, the increasing speed of innovation, rapid global diffusion of technology, and adversaries who take advantage of these, will be key factors for the United States and the DOD to manage in the coming years. The U.S. Defense Science Board (DSB), in an April 2025 unclassified report, indicated similar assumptions.[4]

Background

History demonstrates that rather than assuming that the next war may be like the last, and that one can rest and enjoy a peace dividend, maintaining peace is best obtainable through the possession of an unassailable military force. Since 1990, the United States, in its role as the world’s sole superpower, has avoided major costly wars on the scale of those that occurred in the first 80 years of the twentieth century. Conflicts during the past 30 years were of regional geographic scope. The Gulf War (1990–91), the Yugoslav Wars (1991–2001), and to a slightly larger extent the Iraq War (2003–11) did not involve massive combat forces during a protracted period that imperiled the production of major war materiel. However, supporting a military force that can react to major challenges requires a strong, well-balanced economy to fund this security capability. This would require both a capable DIB and a strong, dynamic domestic industrial base (DoIB) or, as the DSB indicated, a national security industrial base (NSIB).[5]

It would not, however, take a war at the scale of World War I (1914–18) or World War II (1939–45) to overwhelm the United States’ current manufacturing capabilities. Being drawn into multiple smaller regional wars in Iran, the Red Sea, the Levant, the South China Sea, or elsewhere could equally overwhelm the nation’s current manufacturing and logistics capabilities. During the past 30 years, the United States has seen massive consolidation in the DIB and a commensurate erosion of production capabilities in response to the collapse of the Soviet Union and the end of the Cold War in 1991. Following these events, the United States optimistically began to reduce its military force structure, principally designed to thwart Soviet aggression, in the hopes of recouping a peace dividend.

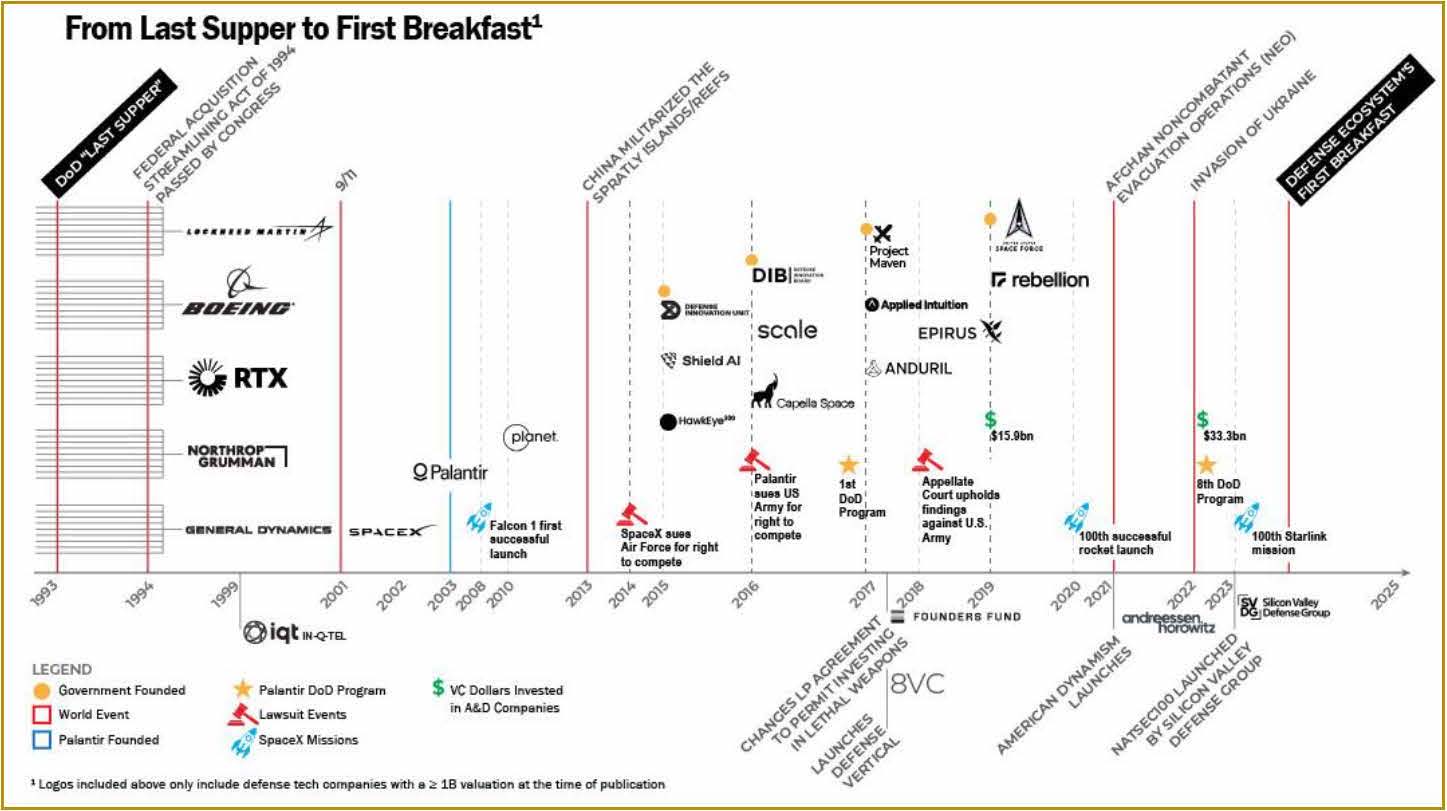

This consolidation was identified in meetings between DOD leaders and companies in the DIB. In July 1993, U.S. secretary of defense Leslie Aspin Jr. invited the chief executive officers (CEOs) of the DOD’s largest defense prime contractors to the Pentagon for a dinner meeting in the secretary’s dining room to discuss the road ahead. The U.S. House of Representatives had just passed the first post-Cold War defense bill earlier that day, and drastic action had to be taken to keep defense spending in line with the current geopolitical environment. This inflection point in the DIB eventually saw a consolidation of surviving prime contractors from an estimated 51 to 5 today. Norman R. Augustine, CEO and chairman of the Martin Marietta Corporation and known for his wit, bestowed the moniker “The Last Supper” on the meeting.[6] A number of mergers involving the “Big Five” U.S. defense contractors have also occurred since 1993.[7] Figure 1 illustrates the effects of the Last Supper in 1993 to the “First Breakfast” in 2024.

Short-term and overly optimistic congressional thinking leading to the Last Supper catalyzed a loss on the part of the DIB to respond quickly to changes in the geopolitical arena challenging U.S. national security interests. Capacity goes away much more quickly than it arrives. Consequently, this loss of industrial capacity amplified globalization trends, and an erosion of U.S. knowledge in manufacturing quickly followed. This has left the United States vulnerable to adversaries who produce needed goods for both the private and defense sectors and dependent on unreliable allies.

Figure 1. Timeline of the Last Supper (1993) to the First Breakfast (2024)

Source: Defense Science Board, 21st Century Industrial Base for National Defense: Final Report (Washington, DC: Department of Defense, 2024), 44, adapted from Shyam Sankar, Greg Little, and Madeline Zimmerman, “From Last Supper to First Breakfast: The Defense Tech Ecosystem,” Palantir (blog), 8 September 2023.

The erosion of U.S. manufacturing prowess is certainly a gray swan, since it was a predictable surprise. Timothy D. Cook, CEO of Apple, made a notable comparison during a 60 Minutes interview in 2015, stating that “The number of tool and die makers in the US could fit in a single room, while in China, they would fill multiple football fields.” His comment emphasizes that the United States severely lacks the tooling engineers needed for the development and construction of modern factories.[8]

The rewards of the post-Cold War peace dividend were not fully realized, even though former Soviet Bloc countries became U.S. allies and were integrated into the global economy. Instead, the United States lost military self-sufficiency. This decline in military self-sufficiency was exacerbated by globalization, which resulted in U.S. companies moving many of their industrial operations overseas to reduce costs. Additionally, advances in technology demand reliance on key minerals such as rare earth elements (REE), which have few domestic sources. The U.S. economy drives economic growth and now leverages more than $50 trillion in equity capital market assets; however, spending on defense is about 3.5 percent of the U.S. gross domestic product (GDP) compared to nearly 5 percent in 1993.[9] The combined shifts in defense acquisition strategy have allowed other countries, and even potential adversaries such as China, to share the burden of supplying the United States with war materiel. The U.S. military is now dependent on other nations for REE (China), steel production (Japan, Korea, and China), shipbuilding (Japan, South Korea, and Canada), warships (the United Kingdom and Australia), jet fighters (France, Germany, and the United Kingdom), tanks (Germany and the United Kingdom), tank armor (the United Kingdom), computer technology (Taiwan and South Korea) and trinitrotoluene (TNT) explosives (Poland, South Korea, India, and Australia). The redirection of investment to other areas of industry in hopes of a peace dividend has reduced U.S. military self-sufficiency.

As part of reaping a peace dividend following the Cold War, then-U.S. secretary of defense William J. Perry directed the U.S. military to adopt a commercial off-the-shelf (COTS) acquisition strategy. Coupled with the reduction in U.S. defense spending, the continued use of commercial just-in-time (JIT) logistics processes for managing assets continued to grow in size and scope, especially in the DoIB. [10] These COTS JIT logistics processes and related commercial software packages were developed to maximize corporate profits, not to ensure military readiness, and they may not always contribute to the DIB’s ability to produce what the military needs in the quantities and at the time and place needed.

There are many ways to manage inventory stock levels. Among the most popular techniques is the JIT process, which was implemented by the automotive manufacturer Toyota in the 1970s.[11] With JIT inventory management, parts and materials are received at the factory just in time when needed for production. Its manufacturing efficiency comes from minimizing inventory costs and optimizing production processes as well as a profit motive.[12] Since the 1970s, JIT has become the dominant method to manage stock levels. However, while it has dominated commercial industries for the past 50 years, it does have risks. The underlying assumptions of the process are uninterrupted and timely replenishment of stock, reliable and stable transportation, and a stable and robust supplier base and networks. Any disruptions will create havoc for production. Because of the stability needed in U.S. supply and transportation chains, it is not well-suited for military needs. Of key importance, these two inventory management approaches—COTS and JIT—played a key role in the COVID-19 pandemic and its resulting negative impacts on all kinds of supply chains. This plays into the key points presented in this article, as the JIT approach could not respond to the many demands for all types of protective gear during the pandemic.

The DOD must plan for disruptions (contested logistics, cyberattacks, transportation outages), demand spikes (unplanned combat operations, disaster relief, humanitarian relief), and supplier outages (business failures, mergers, decisions to discontinue products). Because of these risks, in sharp contrast to JIT, the U.S. military does—and must continue to—maintain a just-in-case (JIC) model for inventory management. The emphasis of this process is on maintaining large inventories to avoid stock outages and to maintain high combat readiness levels. Table 1 offers some comparisons between the JIT and JIC models.

Table 1. Comparison of salient features of JIT versus JIC

|

Purpose

|

JIT

|

JIC

|

|

Best use

|

Commercial predictable lean manufacturing

|

Military combat operations, emergency response, and high-uncertainty operations

|

|

Objective

|

Minimize inventory on hand to reduce costs

|

Maximize combat readiness by maintaining additional or buffer stock

|

|

Assumed risk posture

|

Stable, robust, predictable supply and transportation chains

|

Uncertain or volatile demand, use, or supply shocks

|

|

Inventory

|

Minimum to none

|

Calculated expected aggregated use based on scenarios prestocked and forward deployed

|

|

Trigger

|

Order/replenish only when needed—driven by demand

|

Anticipatory—driven by expected risk

|

Source: courtesy of the authors.

Within the JIC process, probabilistic models, largely derived from operational use data and expected scenarios, are used by military logistics planners to determine stock levels. A demand probability distribution will incorporate historical usage rates, failure modes and effects analysis, reliability rates, and expected operational and environmental context variables.[13] Combat readiness sparing is largely determined by parts criticality, reorder/replenishment times, stock depth and usage rates, supply priority, parts location (forward deployed, unit level, or central warehouse) for transportation time, and aggregation of all expected planning scenarios by parts commonality or platform. Finally, inventory levels are typically set to achieve a 95- to 99-percent demand satisfaction level that directly translates to combat readiness level. JIT inventory saves costs and measures lost customers and customer satisfaction relative to any late deliveries. Contrary to the JIT paradigm, JIC inventory and methods do what no COTS system does. The JIC model preserves military capability and combat readiness, estimates deaths of troops and losses of material, and evaluates the probabilities and consequences to a nation of losing battles and wars. The JIT versus JIC discussion is important for continued discussion, especially with regard to key REE and metal products, since these are critical to almost all military materiel.

Security Challenges

In addition to the logistics inventory approaches mentioned above, the United States today faces the broadest range of conflicts by type, temporal, technological, and geographic scope—outside of an active world war—in its history. The 2024 Annual Threat Assessment of the U.S. Intelligence Community, published by the Office of the Director of National Intelligence, identifies additional perils.[14] These include the rise of China as a global military and economic power; Russia’s ties with China, Iran, and North Korea and its goal of reducing U.S. influence globally by applying military intimidation and leveraging its energy reserves; India’s rise as a major secondary player seemingly aligned with both the United States and Russia as well as its challenges with neighboring Pakistan; a dangerously unstable nuclear power in North Korea; Iran’s nuclear and regional hegemonic desires in the Middle East; widespread terrorism; invisible cyber attackers; and crime syndicates able to coerce or topple governments.[15] Individually, these perils strain the United States’ military preparedness, and a simultaneous realization of multiple threats would arguably overwhelm the nation’s warmaking and defensive capabilities.

U.S. statecraft exerts influence by applying diplomatic, informational, military, and economic (DIME) levers to protect vital interests. While the use of conventional weapons by the United States has generally had a deterrent effect on its adversaries, during the past three years more than 40 articles have illuminated the substantial logistical challenges within the U.S. military and the DIB that undermine this ability to prevent conflict. Some DOD officials argue that the United States should have a military deterrent presence across all warfighting domains and the full spectrum of conflict.[16] This deterrent effort puts the United States and its allies in a position to avoid economic insecurity or even armed conflict. National security and economic security are two sides of the same coin. The United States requires both a military and the defense infrastructure that supports it to function together as a successful deterrent to aggressors, prevent interdictions of world trade, and supply friendly nations with the means to repel attackers with or without the direct involvement of U.S. troops. The two goals of maintaining a strong economy and strong military are mutually supporting.

While the current administration of U.S. president Donald J. Trump is enhancing the readiness of the military, the larger DoIB must also be strong, productive, and highly innovative to develop a variety of multiuse high-technology capabilities to support the DIB and DOD. Indeed, multiple authors argue that current administration initiatives are very helpful. The United States needs to repair its military infrastructure to regain “great power” supremacy. Christian Brose suggests in The Kill Chain that key changes for future military readiness are necessary.[17] Authors such as Jerry Hendrix, A. Wess Mitchell, and Ionut C. Pop have also written about great power challenges.[18] Currently, personnel shortages, heavily used or outdated equipment, and increased operational tempos all contribute to a lower readiness posture that affects the U.S. military’s great power capabilities.

One critical reason to maintain the readiness of the U.S. military with a JIC model is the global interconnectedness of the modern world. For example, a major suspension of the flow of petroleum or a refusal to sell vital raw materials could severely damage economies around the globe. Stable energy supplies and critical REE and other key metals are vital for modern manufacturing, modern economies, continued innovation, and skilled workforces. For these reasons alone, business deals may not be sufficient to maintain stability. The power to protect the nation and the flow of goods is essential for the continued economic growth of the United States and the world. Most recently, this was evidenced by the U.S. Navy deploying forces to the Red Sea to maintain free passage of shipping, benefiting Europe and Asia. This is also, however, an example of a conflict that is contributing to the strain on the supply of U.S. munitions.

For the United States to maintain its great power status, to remain at the forefront of technology, and to be self-reliant, many industries are essential for ensuring a strong military. These industries include shipbuilding, aviation, space technology, computer technology, artificial intelligence (AI), robotics, quantum computing and communications, cybersecurity, and superior dual-use consumer goods. Being a leader in these and other critical industries requires a heightened sense of national urgency. In the past, research demands by the military have often been at the center of advances in these areas, but this has lagged in recent decades. U.S. capacity in many areas is also challenged and strained. Examples include shipbuilding and repairs (particularly for the U.S. Navy), low-cost long-range missiles, antiship cruise missiles, and advanced manufacturing of artillery munitions. A significant facet of the United States’ postwar strategy for peace and economic growth following the end of the Cold War was to build up other countries’ industrial capabilities and capacity, often at the expense of U.S. self-reliance. An unintended consequence for the U.S. military has been a slow, steadily upward trend in reliance on imports for key materials and production capability.

Logistics Concerns

Recently published executive orders from the White House also speak to the size and scope of the challenges that the United States faces.[19] In response, the establishment of the Manufacturing Innovation Institutes (MIIs) shows the United States moving forward with new initiatives to reinvent and reshore manufacturing, enhancing defense supply chains and contributing to national economic growth. As added background, a recent July 2025 report by the Baroni Center for Government Contracting at George Mason University entitled Government Contracting Trends and Performance Index has provided an inaugural and very thorough assessment of the impact of the DIB and DoIB on overall government contracting. This new report highlights continued challenges with laborious government contracting that impact all aspects of manufacturing and is a report of high concern to the authors.[20]

While these steps are important, this article will focus on specific DIB challenges of immediate concern by means of three problem sets, with the final example a notional scenario of production and delivery of an advanced missile system.

The emphasis of this article will be on manufacturing capabilities and logistical challenges in three topical areas: key artillery munitions, rapid advancement of drone technology, and missile adaptation efforts to project power globally. These areas suffer from production bottlenecks, REE needs, manufacturing challenges, lengthy contracting, limited domestic logistics ship availability, and other shortcomings. The detailed missile example described will highlight production and delivery concerns. The authors will address ship repairs and shipbuilding in a separate paper due to its unique supply chains and labor force challenges, as the current U.S. Merchant Marine fleet has fewer than 170 vessels compared to more than 550 at the end of the Vietnam War in 1975.[21]

Key Artillery Munitions

A significant strain on the demand for artillery shells emerged due to the Russo-Ukrainian War. Many pundits thought that the Russian invasion of Ukraine in February 2022 would lead to a blitzkrieg across Ukraine, but Ukrainian forces demonstrated significant courage, prowess, and innovation in stopping the Russian advance. Reverting to tactics reminiscent of World War II, the war is now in its fourth year, with Ukraine calling for massive numbers of artillery shells to blunt Russian advances. Artillery munitions produce up to 80 percent of casualties in the war and are critical to Ukraine’s survival.[22] However, U.S. and North Atlantic Treaty Organization (NATO) promises to provide the artillery munitions required have been unfulfilled. An example is given in numerous articles evaluating the supply of 155-millimeter munitions.[23] After repeated promises, and despite having had four years to increase production, the European allies are still lagging in delivering the quantities needed of these artillery shells.

The artillery demand signal from Ukraine is estimated to be 180,000 rounds a month, with potential demand for even higher quantities.[24] Russia alone has produced more artillery rounds than the combined efforts of the United States. and NATO. In addition, Russia is obtaining artillery projectiles and systems from North Korea, with the combined production of both countries further surpassing the total Western output.[25] This production disparity has occurred for several reasons:

- U.S. munitions production has decayed during the past 40 years. In 1980, U.S. ammunition plants could produce 438,000 rounds per month. Of note, former undersecretary of defense for acquisition and sustainment William A. LaPlante said, “Since the end of the Cold War, defense industries have not been doing much production work for the department.”[26] As the adage goes, “if you don’t use it, you lose it.”

- In the summer of 2021, prior to the Russian invasion of Ukraine, the U.S. Army requested to cut annual spending on 155-millimeter ammunition by half to an annual production rate of 75,000 rounds, believing that the sun was setting on artillery in the modern battlefield.

- By March 2023, NATO could produce only 20,000 rounds per month, while the United States produced roughly twice that.

- A report by the Army Science Board in September 2023 highlighted many difficulties with the Defense Munitions Industrial Base (DMIB), citing serious issues of supply chain fragility, faulty planning, complex chains of authority, manufacturing defects, old equipment, and other problems that hamper the production of artillery rounds.[27]

To build production to 1.2 million rounds annually, Congress gave the Army $6.4 billion in April 2024. The United States planned to achieve a production rate in late 2024 of around 80,000 rounds per month (960,000 per year) for 155-millimeter artillery to support Ukraine. However, Reuters News indicated problems in July 2024, suggesting that the United States would not meet this goal.[28] Other reports indicated that the NATO allies promised much and fell behind in delivery of artillery munitions.[29] In congressional testimony on 12 March 2025, the vice chief of staff of the Army, General James H. Mingus, indicated that the 80,000 per month quantity of artillery rounds would likely be met in the summer of 2025, nearly three and a half years after the Russian invasion of Ukraine.[30] The NATO allies promised similar production levels and failed.[31] Table 2 offers a simplified view of the artillery munitions picture in the Russo-Ukrainian War, detailing some production volumes for key artillery weapons systems and revealing the magnitude of some deficiencies.

Table 2. Artillery munitions estimates (Russo-Ukrainian War)

|

Year

|

Quantities of 155-millimeter artillery shells (best estimates)

|

Quantities of 152-millimeter artillery shells (best estimates)

|

|

2024

|

United States alone

|

840,000

|

Russia alone

|

3 million

|

|

2024

|

United States and NATO

|

1.2 million

|

Russia and North Korea

|

Between 4 to 6 million

|

|

2026

|

United States alone

|

1.2 million

|

Russia alone

|

3.2 million

|

|

2026

|

United States and NATO

|

2.2 million (approximate)

|

Russia and North Korea

|

More than 6 million

|

Note: there are some discrepancies in U.S. and NATO production numbers due to conflicting source reports.

Source: courtesy of the authors.

When Hamas attacked Israel on 7 October 2023, the shortage of munitions for Ukraine was exacerbated. This second conflict theater put greater strains on U.S. logistics as Israel needed an immediate increase in supplies of 155-millimeter artillery shells, some of which were diverted to or from other theaters. This conflict in the Middle East expanded with the addition of Hezbollah elements in Southern Lebanon and Houthi rebels in Yemen. Urban fighting in Gaza and southern Lebanon added to the Israel’s demand for munitions through the large expenditure of artillery and mortar rounds needed to defeat Hamas and Hezbollah.

Besides the demand for completed shells, a major bottleneck in artillery munition production is the lack of domestic industrial base providers for the TNT component. The United States even had to import TNT from foreign sources such as India while a new contract was awarded for a plant in Kentucky, which will come online in 2027.[32] The TNT oversight by the DOD was incredible.

Rapid Advancement of Drone Technology

The current artillery munitions shortage has been partially solved by the belligerents’ novel use of drones and missiles. Drone technology can be placed in three generic categories:

- Aerial drones, also referred to as uncrewed aerial systems (UAS). These became more prevalent as lower-priced commercial variants became available.

- Uncrewed surface vessels (USV) and uncrewed underwater vessels (UUV).

- Uncrewed land surface vehicles (robotic vehicles).

Ukrainian drone experimentation, development, and modification during the past three years has been impressive. Ukrainian efforts effectively achieved production at the “need of speed” to counter Russian artillery, mitigate superior Russian firepower, and frequently intimidate Russian troops.[33] Ukrainian drones have gained potential parity of capability in specific categories with those of adversaries and perhaps the United States.[34] Ukrainian aerial drones successfully attacked an array of Russian energy sites and transportation nodes.[35] These real-world beta tests led the DOD’s Defense Innovation Unit (DIU) to contract with two Ukrainian companies for long-range, one-way aerial drones.[36]

The Russian military has been supplied with Iranian HESA Shahed 136 aerial drones as well as other organically produced drones to conduct artillery spotting missions, electronic warfare operations, and carry out other tasks.[37] In contrast, the European Union remains sluggish in dealing with the proliferation of relatively low-cost drones to support Ukraine on the scale needed, and the outlook for producing drones at that scale needed is doubtful.[38]

Ukraine has extended its victories to the seas, employing USV drones to keep the ships of the Russian Navy’s Black Sea Fleet at bay in ports farther away from Ukraine.[39] During the past three years, this tactical and technological approach has proven effective with low-cost USVs marginalizing high-cost naval platforms, resulting in the Russian Navy losing nearly 30 percent of its Black Sea Fleet vessels.[40] In the Black Sea, the Ukrainians have achieved impressive “area denial” outcomes to hamper the Russians, including an alleged attack downing a Russian jet in 2025, as well as attacking bridges and other Russian infrastructure with USVs.[41] These successes have led various NATO nations to develop similar capabilities for maritime area denial purposes.

The Houthis have also emerged as crafty warfighters by employing UASs, USVs, and missile attacks on Red Sea shipping. Russia’s foreign military agency is probably providing technical assistance to enhance Houthi military operations under the guise of humanitarian aid. Houthi aid is also alleged to come from Russian arms dealer Viktor Bout as well as China.[42] The aid from these two nations to the Houthis potentially added more chaos to the transit of the Red Sea. The Houthis’ use of waterborne drones showed surprising speed of development and effective employment. Not only were commercial vessels of nonbelligerents targeted but U.S. Navy and allied naval vessels were also attacked.[43] These strikes disrupted global trade and increased commercial shipping costs due to rerouting vessels around the Cape of Good Hope to avoid the Red Sea. For example, the world’s largest container shipping firm, Mediterranean Shipping Company, redirected ships to take the longer route around Africa’s southern tip as recently as January 2025, with a reported 70 percent of ship traffic avoiding the Red Sea.[44] These developments have changed ship traffic at a huge economic cost.

The surprise use of water surface drones and an underwater drone by the Houthis has been unsettling. Some news agencies have reported more than 400 Houthi attacks against all shipping in the past 18 months.[45] The U.S. Navy has repelled Houthi attacks effectively, albeit by employing hundreds of high-cost missiles in defense against low-cost adversary missiles and drones. This has exposed a cost imbalance that can strain U.S. missile production materially and economically. Recent reports have indicated that the United Kingdom and France are also providing naval vessels in the region for the protection of commercial shipping, which further emphasizes the United States’ reliance on allies to complete its mission.[46]

These Houthi multidomain attacks by means of air and sea show modern technologies achieving both aerial denial and antiaccess goals. Aerial drones can attack without warning, are cheap to use, and are difficult to defeat. Small water surface vessels are inexpensive to employ and cause increased need for close-in protection of naval vessels. The range at which attacks can be made has increased exponentially along with payload capacities, with one example being a May 2025 missile attack on the Ben Guiron airport in Tel Aviv, Israel.[47] In response, the United States and allied nations must accelerate counterdrone systems for the protection of their fleets, key bases, command and control centers, critical transportation nodes, frontline troop units, and vital infrastructure. Defense against drone and missile attacks was a crucial point of discussion regarding Joint Force readiness at a U.S. Senate hearing on 12 March 2025.[48]

U.S. industry has responded to these calls for action. Recent articles have highlighted DIB companies such as Anduril and Palantir making rapid advances in aerial and water surface drone capabilities as well as other leading-edge technologies for the DOD.[49] Several other U.S. firms are ramping up counterdrone defensive options. Hopefully, the DOD and the DIB will react quickly and effectively to get ahead of the drone innovation curve set by the United States’ adversaries. The need for a swift response to these evolving threats to U.S. territory, brought into focus by news reports of drones over northern New Jersey last November, should warn the U.S. Department of Homeland Security to prepare for drone defense across the homeland. Table 3 shows examples of the proliferation of aerial drones in the Rossu-Ukrainian War. Comparisons can be difficult as many of these types of drones are relatively inexpensive and would be considered in the Class 1–3 types by the DOD.

Table 3. Aerial drone production examples for the Russo-Ukrainian War

|

Country

|

Total estimated number of aerial drones

|

Year

|

Comments

|

|

Ukraine

|

1.2 million (produced in Ukraine)

|

2024

|

Defense experts believe that Ukraine will produce more than 2.5 million in 2025. About 90 percent are first-person-view models.

|

|

Russia

|

32,000 to 62,000

|

2024

|

This estimate does not include Shahed 136 drones from Iran. Russian numbers should increase to approximately 70,000 by end of 2030.

|

|

Iran

|

8060

|

2024

|

Iran delivered this quantity in 2024. Most drones were Shahed 136 models.

|

|

NATO

|

Promised 1 million drones

|

2024

|

The authors can only find evidence of 6,555 drones delivered in 2024. This includes U.S. numbers.

|

Note: information sourced from David Hambling, “1,200,000 Drones: Ukraine’s Unmanned Weapons Are Transforming Warfare,” 1945, 9 January 2025; Alexander Marrow, “Russia to Produce over 32,000 Drones Each Year by 2030,” Reuters, 6 January 2024; Brandon J. Weichert, “Russia Launched 8,060 Iranian Shahed-136 Drones against Ukraine in 2024,” National Interest, 9 January 2025; and Vadim Kushnikov, “NATO Countries to Provide Ukraine with 1M Drones in 2024,” Military NYI, 15 February 2024.

Source: courtesy of the authors.

Missile Adaptation

While effective use of U.S. and NATO missile systems such as the M142 High-Mobility Artillery Rocket System (HIMARS) was certainly made, Ukraine also adapted to conventional artillery munitions shortages with drone technologies and by the development of new missile systems or missile modifications. They Ukrainians modified or created effective, rapidly manufactured weapons, such as their homemade cruise missile Neptune. The success of Ukrainian missile innovation can be seen in their destructive attacks against Russian oil and gas sites in recent months.[50]

Potential aggressor nations are also engaged in the missile arms race. Iran has developed or improved many types of missiles offering enhanced range, lethality, and speed compared to earlier versions.[51] These upgraded weapons are provided to their proxy agents, such as Hamas, Hezbollah, and the Houthis, increasing the number of potential adversaries able to launch disproportionate threats. Moreover, trips by Iranian officials to Venezuela for key REE materials and other key metals should make the United States and its allies apprehensive, as the Iranians may gain advances in upgrading missile capabilities.[52] The recent air attacks by Israel and the missile responses by Iran in June 2025 indicated another possible grey swan event—the launch of one potentially hypersonic missile by Iran that allegedly attained a speed more than Mach 5 and that landed in Israel.[53] Such aggressor proliferation will place further strain on the ability of the United States and its allies to produce antimissile defenses.

More U.S. companies are investing in missile component production, which should assist with capacity and capability for the DOD. Aerojet Rocketdyne, recently acquired by L3Harris, is building new production facilities in two states to accelerate manufacturing processes.[54] This is one example of the manufacturing innovation needed to support national defense, but more is called for in the future. A notional missile example in table 4 provides specific details regarding likely challenges.

The Logistics Challenges: A Notional Missile Production and Delivery Example

The two recent conflicts discussed above have laid bare the inability of the United States to supply the requests from Ukraine and Israel for kinetic munitions while at the same time meeting the demands of its own military forces and allies globally.[55] The missile challenge has been perplexing, both in terms of acquiring critical materials and the need by the United States and its allies to provide both offensive and defensive capabilities. As a notional example, U.S. advanced defensive and offensive missile batteries have been in demand because of their superior battlefield performance. With the increased capabilities of other actors to reach the United States, domestic demand for missile defense is more urgent, requiring greater production of existing or new systems.

This raises the question: after completing the appropriate approval processes, how long does it take to manufacture, transport, and deliver vital missiles to U.S. forces who may be forward deployed? Table 4 lists notional steps to identify challenges in production, labor hiccups, continuing resolution (CR) impacts, and other possible disruptors to illustrate breakpoints.

Table 4. Hypothetical missile logistics scenario

|

|

|

|

Need is identified for additional missiles beyond current contracted level. Procurement is initiated.

|

Final assembly at a location within the continental United States (CONUS); supply distributed chain across multiple states.

|

9 months planned; 3 months actual due to contract negotiations with subcontractors.

Running total: 13 months

|

|

Work begins. Interdependency of primes and subcontractors (e.g., Boeing is a subcontractor to Lockheed Martin for a particular missile) incurs risks to production priorities and timelines.*

|

At prime contractor final assembly site and subcontractor locations nationwide.

|

18-month planning factor.*

Running total: 31 months

|

Prime contractors identify defects in components using imported REE.

Prime notifies the U.S. government and initiates remediation across supply chain.

|

Final assembly site and subcontractor sites.

|

6-month delay to remove and inspect all components from assembled missiles and in the supply chain.

Running total: 37 months

|

Labor strike occurs at final assembly site due to increased production requirements and lack of experienced supervisors. Previous funding disruptions (e.g., CR) disrupted workforce and management pool.

|

Assembly line stopped at prime contractor’s final assembly site.

|

1-month disruption to final assembly and inspection.

Running total: 38 months

|

Additional missiles produced and inspected by prime contractor.

|

|

38 months for procurement, production, final inspection, and acceptance by the U.S. government.

|

Missiles shipped to port for surface movement to theater.

|

|

2 weeks

Running total: 38.5 months

|

Cyberattack occurs on cranes at seaport.

|

|

|

|

|

|

|

Missiles are in transit. Ship hits rough seas and takes a longer route.

|

Theater distribution hub.

|

2 weeks

Running total: 39 months

|

Ship arrives in allied nation port for customs, unloading, etc.

|

|

|

|

|

|

|

|

|

*Information based on an assessment in Defense Science Board, 21st Century Industrial Base for National Defense: Final Report (Washington, DC: Department of Defense, 2024), 38–44.

Source: courtesy of the authors.

Although table 4 is speculative, even if it is off by a few months, it highlights a major problem. Approximately 33 percent of the initial planned total time in the table was for contract negotiations and award. If the entire supply chain were built further and subjected to a reliability and availability analysis and failure mode and effects analysis, other problems would likely be exposed. Examples are a lack of skilled labor, dependency on other nations for REE and computing components, and other single points of failure outside U.S. control. Imagine, in a wartime scenario, the outcome if replacement missiles of several types took two years to reach the theater. Even in the slower-moving battles of World War II, this may have dramatically changed the course of the campaign or the outcome of the war. Indeed, compare today’s timeline to the 143 days it took the Lockheed Advanced Development Projects (a.k.a. “Skunk Works”) to develop the first U.S. jet, the P-80 Shooting Star, during World War II. If the United States faces multiple conflicts or an existential threat, today’s timelines are simply unacceptable.

DOD, DIB, and DoIB Challenges

In the Russo-Ukrainian and Israeli-Hamas conflicts noted above, allies, adversary nations, and other groups are deploying near-equivalent capabilities at faster rates, higher volumes, and at lower cost points than the United States. Recent examples of UAVs, USVs, and rapid “low-cost” missile developments have shown that adversaries are reaching a level of parity in offensive capability and more rapid replenishment rates than the United States. The once-magnificent manufacturing prowess of the United States has been ceded to other nations. Some of these countries do not have the contracting regulations that the United States employs, and they often have stockpiles of REE and other key metals. In addition, their “top-down” leadership has more authority to shorten the decision cycle to produce items. Many of these countries also have workforces trained by U.S. companies that outsourced manufacturing to get cheaper labor while the U.S. skilled labor force dwindled.

The recent U.S. Senate Subcommittee on Readiness called for the nation’s military Services to develop and publish a Service-centric DIB strategy, with specific objectives, to be shared with the Senate.[56] This initiative calls for better positioning all parties to move forward in accelerating funding, contracting, and manufacturing actions regarding counterdrone options, advanced missiles, and more innovation to best position the United States for any possible future armed conflict. During this hearing, the U.S. Navy’s vice chief of naval operations, Admiral James W. Kilby, suggested new language in CRs to give the Navy and the DOD added flexibility in multiyear funding authority. The suggestion was for all CRs and future budgets to authorize multiyear funding for all types of funding accounts to minimize production disruptions and schedule challenges. The senators seemed amenable to these suggestions for changes to cross fiscal years, even in CR funding.

Defense contracting is also a challenge for many companies, especially new companies entering the DOD national security ecosystem. Some new companies have had success and have shown a good deal of innovation, but the DOD needs to consider ways to improve contracting and ensure that critical emerging technologies gain access to the larger DIB ecosystem. There is some hope on the horizon as a number of new companies have entered the DIB ecosystem. However, this is just an example of the hundreds of companies working to obtain DOD contracts and enter the DIB ecosystem. The entry into the DIB still remains challenging. Table 5 lists some companies that have had success.

Table 5. Examples of relatively recent companies in the DIB ecosystem

|

Space X

|

Vannevar Labs

|

|

Anduril

|

Epiros

|

|

Palantir

|

Clarifai

|

|

Shield AI

|

Scale AI

|

|

Applied Intuition

|

Firestorm

|

Note: this table only lists a fraction of new entrants into the DIB ecosystem. The authors used this information simply to illustrate the point of these organizations having learned how to obtain and manage contracts with the DOD.

Source: courtesy of the authors.

It has become evident that the United States does not have a sufficient DIB manufacturing base to rapidly meet national needs for multifront and multidomain conflicts at the speed and scale that the authors believe necessary. Funding difficulties, arcane planning, contracting and budgeting processes, lack of organic commercial manufacturing capacity, fettered access to REE materials and other key metals or materials needed for production, regulatory frictions in building new capacity, and a general lethargy in fixing longstanding problems contribute to the manufacturing deficit in the DIB. In addition to these comments by the authors, the Govini 2025 National Security Scorecard: Defense Acquisition Critical Capabilities indicated that the DIB is simply not prepared for conflict.[57] This report confirms what the authors have discussed in this article and indicates a lack of readiness.

Suggestions

The following paragraphs offer suggestions for how the DIB can improve to meet the needs of the United States and prepare for conflict.

Contracting

A new metric should be instituted by the DOD for no more than 90 days to get tasks on contract. Many companies in the DIB and the larger DoIB use a 90-day goal to start work and include incentives for delivering products on time or ahead of schedule. Adding targeted incentives to increase performance, reduce cost, and deliver early to achieve the “need of speed” would be beneficial. The contracting process, with its attendant need for funding, requirements definitions, statements of work, and other actions, shows that linear and sequential processes require faster action. Some contracts could be kept in place so the DOD can just hit the “buy” button.

Rare Earth Elements and Key Metal Needs

Coordination should be improved with the Defense Logistics Agency and other partners in the U.S. government to upgrade REE outcomes, as well as for other key metals and materials for the DOD and DIB. Focus should be on minimizing backlogs and doubling stockpiles. National stockpiles should be maintained at an adequate JIC level that allows production during grey swan events when an enemy will deliberately destroy fragile JIT supply lines to prevent U.S. involvement in conflicts or as a means of defeating the United States before the fight even begins.

Use of Artificial Intelligence for Workflows

AI tools should be considered to improve contracting and manufacturing processes, workflows, and simulation for better outcomes. AI should also be used to assess methods to speed up contracting to meet rapid goals and other processes. In addition, perhaps an example of the entire 155-millimeter artillery logistics network could be diagrammed or identified with the assistance of AI tools to improve effectiveness and perhaps unseen supply topics especially in the entire contracting, production, and delivery phases. Reliability, availability, and failure mode and effects analysis should be done for the manufacturing supply chains from resource to factory for all critical military materials.

Skilled Labor

Options should be reviewed for increasing skilled labor as soon as possible for advanced manufacturing, specialty skills, and use of robotics. Realignment of U.S. Department of Education funds should be considered to enhance trade schools, provide certifications for skilled labor, create internships, and so forth. Skilled labor is a strategic requirement for manufacturing tasks for national defense.

Immediate Legislation for DOD Funding Flexibility

In congressional testimony on 12 March 2025, all the U.S. military Service vice chiefs highlighted the need for multiyear funding given the constant use of CRs. Multiyear funding and other funding flexibility options must be included in future legislation, requiring the Services to collaborate to bring these notions to Congress for approval. Congress must act now to provide DOD leadership with improved funding authorities.

New Military Service DIB Strategy

Each U.S. military Service should provide the Senate with their DIB strategy to improve logistical outcomes for the future. The presidential administration should then integrate the Services’ individual strategies into an integrated grand strategy to ensure that the DIB is integrated with a Joint Force capable of defending U.S. interests globally.

Study and Apply Lessons Learned

The United States should study success stories such as Ukrainian advances in missile and drone technology. Such lessons learned should be applied by U.S. firms as an example of how to ramp up production rapidly and employ innovations swiftly during a time of war.

Invest in Dual-Purpose Manufacturing Facilities

Companies should be invested in and incentivized to make dual-purpose factories so that commercial assembly lines can be reconfigured to make military equipment in a time of military need.

Create New DOD Vendors

It would benefit the DOD if the Defense Contract Management Agency were to provide frequent conferences around the United States to encourage new companies to enter the DIB ecosystem and to assist with some instruction on the processes. Other DOD agencies have done this effectively. This notion may assist with bringing innovation into the DOD faster and may increase the number of companies that manufacture military equipment.

Conclusions

This article asked whether the United States is prepared to fight a war under the current circumstances prevailing in the twenty-first century. Winning a multifront, multidomain, high-technology war will be challenging at best for the United States. Adversaries lose the will to fight through pressure and the potential of large-scale destruction. Munitions, missiles, and drones are essential for causing that loss of will and are foundational to winning. The present U.S. industrial capacity cannot meet the demand for munitions, missiles, and drones to support Ukraine and Israel. How then, can the United States deter adversaries from escalating? If additional demands are placed on the DIB and logistics chains to fight a multifront conflict, it may collapse. The slowness of the U.S. contracting processes, the inability to rapidly scale the U.S. manufacturing base, and the lack of organic domestic supplies of REE and other raw materials critical for making U.S. weapons systems all foreshadow major challenges for multifront conflicts. Without correcting these deficiencies, the authors believe that there will be more conflict globally, and should a major conflict arise, the United States may lose, attain a draw, or be unable to risk entering the fight altogether. The United States may, therefore, be the weaker party when negotiating.

The United States faces large challenges. While all the above inputs and comments in the three examples provided in this article are primarily tactical in nature, the United States must take a better strategic view of the massive great power challenges facing it.[58] There are requirements for immediate legislative improvements to assist the DOD, the DIB, and the larger DoIB to improve capacity, capability, and whole-of-government approaches to improve security and provide a new whole-of-government logistics strategy. Alarming reports from the DSB present a doubtful future for the United States unless critical changes are enacted.[59] The United States is vulnerable to a gray swan event, to which it would respond too slowly.

Given the increasing collaboration for foreign incursions among China, Russia, North Korea, and Iran, their ability to control organic manufacturing, alternative funding approaches, large access to REE and REE stockpiles, shipping assets, and engineering skills means that they are capable of creating gray swan events and may well have an advantage in exploiting such events. With the current status of the DIB, a coordinated effort by these U.S. adversaries, or simply the coincidental escalation of current conflicts around the world, could present an existential threat to the United States in a conflict on multiple fronts over expanded geographical and domain areas. Compounding this threat are small client states or other actors that can inflict disproportionate damage, such as attacks on shipping by the Houthis or cyberattacks by criminal organizations.

The problems highlighted here will not be solved by a continuation of “business as usual.” The United States’ DIB must regain the competitive advantage. Moreover, the DOD and DIB will have to adapt to the cost asymmetry uncovered in this article. The Ukrainians and Houthis in particular are examples of “David fighting Goliath.” They are inflicting damage, achieving geographical area denial, and creating an unsustainable high-cost exchange ratio for the United States. The United States cannot ignore this cost and warfighting asymmetry, and the DIB must become competitive by designing and manufacturing more effective weapons at a lower cost, as well as be more responsive, as recently mentioned by U.S. secretary of the Army Daniel P. Driscoll.[60]

In warfare, speed, cost and effectiveness matter. From Sun Tzu to Douglas MacArthur, being late to meet the needs of warfighters typically means failure. The ability of the United States’ adversaries to adopt new technologies and adapt them to modern warfare exceeds that of the United States. The nation almost habitually relearns lessons of the past, where the disadvantaged party cleverly innovates and improvises to defeat expensive weapons with inexpensive ones or alternative tactics, making the old weapons obsolete. The unfavorable economic exchange ratio further exacerbates U.S. production problems. What is good for profits is sometimes bad for the nation, which in the long run is bad for everyone. Innovation, more cost-effective weapons, more and faster manufacturing, improved supply chains from raw resource to factory, and improved supply chains from factory to the front are all needed to ensure that the United States remains a great power.

Perhaps those who must institute changes in the current system should refer to the book An Unknown Future and a Doubtful Present: Writing the Victory Plan of 1941 by Charles E. Kirkpatrick as a backdrop to overcoming past national challenges.[61] To paraphrase George Santayana, learning from history is crucial to avoid repeating past mistakes and ensuring better future outcomes. To sustain and win critical multifront conflicts, the United States must move out now with a greater sense of urgency for domestic manufacturing and a whole-of-government approach to win.[62] The DOD and DIB must have improved processes and a realistic national logistics strategy for the safety and security of the nation based on an updated national grand strategy in this chaotic world.

Endnotes

[1] Donald J. Trump, “Restoring America’s Maritime Dominance,” Executive Order 14269 (Washington, DC: White House, 9 April 2025); and Donald J. Trump, “Modernizing Defense Acquisitions and Spurring Innovation in the Defense Industrial Base,” Executive Order 14265 (Washington, DC: White House, 9 April 2025).

[2] David Barno and Nora Benashel, “America Is Not Prepared for a Protracted War,” War on the Rocks, 4 December 2024; John G. McGinn, Before the Balloon Goes up: Mobilizing the Defense Industrial Base Now to Prepare for Future Conflict (Fairfax, VA: Costello College of Business, George Mason University, 2024); and Marcos A. Melendez III, Michael E. O’Hanlon and Jason Wolff, “America Can’t Afford to Ignore the Logistics Triad,” Brookings Institute, July 2023.

[3] Becca Wasser and Phillip Sheers, From Production Lines to Front Lines: Revitalizing the U.S. Defense Industrial Base for Future Great Power Conflict (Washington, DC: Center for a New American Security, 2025).

[4] Defense Science Board, 21st Century Industrial Base for National Defense: Final Report (Washington, DC: Department of Defense, 2024), 2–5.

[5] 21st Century Industrial Base for National Defense, 4, 43.

[6] Daniel Gouré, “The Next ‘Last Supper’ Will Be the Last ‘Last Supper’,” Lexington Institute, 29 November 2011.

[7] 21st Century Industrial Base for National Defense, 44.

[8] Interview with Timothy D. Cook on 60 Minutes, season 48, episode 14, “Inside Apple,” aired on CBS News, 20 December 2015.

[9] 21st Century Industrial Base for National Defense, 8–12.

[10] Georgia Collins, “Timeline: The History of Just-in-Time Manufacturing,” Manufacturing Digital, 1 December 2021.

[11] Viral Patel, “Just-in-Time Logistics: What It Means and Why It Matters,” Analytics Magazine, 30 August 2023, https://doi.org/10.1287/LYTX.2023.04.01.

[12] Willy C. Shih, “What Really Makes Toyota’s Production System Resilient,” Harvard Business Review, 15 November 2022.

[13] Shih, “What Really Makes Toyota’s Production System Resilient.”

[14] Annual Threat Assessment of the U.S. Intelligence Community (Washington, DC: Office of the Director of National Intelligence, 2024).

[15] Tom Porter, “India Says It’s Targets Pakistan’s Air Defenses, as Drone Warfare Spreads,” Business Insider, 8 May 2025; and Christopher S. Chivvis and Jack Keating, “Cooperation between China, Iran, North Korea, and Russia: Current and Potential Future Threats to America,” Carnegie Endowment for International Peace, 8 October 2024.

[16] David Vergun, “Official Says Integrated Deterrence Key to National Defense Strategy,” DOD News, 6 December 2022. Domains include, at minimum, land, maritime, air, space, and cyberspace.

[17] Christian Brose, The Kill Chain: Defending America in the Future of High-Tech Warfare (New York: Hatchette Books, 2020).

[18] Jerry Hendrix, “The Return of Great Power Competition,” Law & Liberty, 1 July 2024; A. Wess Mitchell, “The Return of Great-Power Diplomacy: How Strategic Dealmaking Can Fortify American Power,” Foreign Affairs, 22 April 2025; and Ionut C. Popescu, “Adapting U.S. Defense Strategy to Great-Power Competition,” Parameters 55, no. 1 (2025): 73–90, https://doi:10.55540/0031-1723.3332.

[19] “Restoring America’s Maritime Dominance”; and “Modernizing Defense Acquisitions and Spurring Innovation in the Defense Industrial Base.”

[20] John G. McGinn et al., 2025 Government Contracting Trends and Performance Index (Fairfax, VA: Costello College of Business, George Mason University, 2025).

[21] “U.S. Merchant Marine Fleet Summary Table, 1946–2016,” U.S. Department of Transportation, n.d.

[22] Mari Saito, “Life on Ukraine’s Front Line: ‘Worse than Hell’ as Russia Advances,” Reuters, 20 May 2024.

[23] Patrick Tucker, “The West Is Underestimating Ukraine’s Artillery Needs,” Defense One, 22 February 2024.

[24] Tucker, “The West Is Underestimating Ukraine’s Artillery Needs.”

[25] Mike Fredenburg, “Why Russia Is Far Outpacing U.S./NATO in Weapons Production,” Responsible Statecraft, 14 August 2024; Katie Bo Lillis et al., “Exclusive: Russia Producing Three Times More Artillery Shells than U.S. and Europe for Ukraine,” CNN Politics, 11 March 2024; and Deborah Haynes, “Russia Is Producing Artillery Shells around Three Times Faster than Ukraine’s Western Allies and for about a Quarter of the Cost,” Sky News, 26 May 2024.

[26] Fredenburg, “Why Russia Is Far Outpacing U.S./NATO in Weapons Production.”

[27] Army Science Board, Surge Capacity in the Defense Munitions Industrial Base (Arlington, VA: Office of the Assistant Secretary of the Army [Acquisitions, Logistics, and Technology], Department of the Army, 2023).

[28] Stephen Grey, John Shiffman, and Allison Martell, “Years of U.S., NATO Miscalculations Left Ukraine Massively Outgunned,” Reuters, 19 July 2024.

[29] “The Commission Allocates €500 Million ASAP,” European Union, 14 March 2024.

[30] “Defense Officials Testify on Joint Force Readiness,” C-SPAN, 12 March 2025.

[31] Sam Skove, “It Takes Europe at Least a Year to Fill a Ukrainian Order for Artillery Shells,” Defense One, 13 February 2024.

[32] Grey, Shiffman, and Martell, “Years of U.S., NATO Miscalculations Left Ukraine Massively Outgunned”; and Bruce Schreiner, “Army Says the U.S. Will Restart Domestic TNT Production at Plant to Be Built in Kentucky,” AP News, 8 November 2024.

[33] Grey, Shiffman, and Martell, “Years of U.S., NATO Miscalculations Left Ukraine Massively Outgunned”; and “Ukraine’s Vampire Drones Terrorize Moscow’s Forces,” Radio Free Europe/Radio Liberty, 5 February 2024.

[34] Wasser and Sheers, From Production Lines to Front Lines; Sinéad Baker, “Ukraine’s Tons of Drone Types Give It Advantages, but also Downsides,” Business Insider, 22 March 2025; and Nathan Ecelbarger, “Realizing America’s Drone Revolution,” War on the Rocks, 28 April 2025.

[35] Jake Epstein, “This Is the Reusable, Plane-like Backfire Drone that Ukraine’s Birds of Fury Use to ‘Carpet Bomb’ the Russians with Mortars and Grenades,” Business Insider, 18 March 2025.

[36] Michael Marrow, “DIU Picks Four Companies, Including Two Ukrainian Teammates, for One-way Drone Prototypes,” Breaking Defense, 14 March 2025.

[37] Isaac Seitz, “The U.S. Army Isn’t Ready for What Is Coming in the Skies Above,” National Security Journal, 28 May 2025.

[38] Rebecca Rommen, “EU Official Urges Nations to Produce Millions of Drones a Year by 2030,” Business Insider, 4 July 2025.

[39] H. I. Sutton, “Uncrewed Platforms Have Been Critical to Ukraine’s Success in the Black Sea,” Royal United Services Institute, 20 August 2024.

[40] Isabel van Brugen, “Ukraine’s Sea Drones Attack Russian Black Sea Fleet Base,” Newsweek, 3 July 2024; and Isabel van Brugen, “Russian Black Sea Fleet Lost Third of Its Firepower since War Began: Kyiv,” Newsweek, 7 February 2024.

[41] Kosta Gak and Eve Brennan, “Ukraine Claims It Destroyed Russian Fighter Jet Using Seaborne Drone for the First Time,” CNN, 4 May 2025.

[42] Fatima Abo Alasar, “The United States’ Houthi Terrorist Designation Unmasks Russia’s Yemen Strategy,” Atlantic Council, 14 March 2025; Peter Suciu, “In Yemen, China Has Quietly Helped the Houthi Militants,” National Interest, 9 January 2025; and Ryan Robertson, “U.S. Confirms Chinese Satellite Firm Helping Houthi Rebels Target Ships,” Straight Arrow News, 18 April 2025.

[43] H. I. Sutton, “Houthi Lethal Underwater Drones Adds New Threat to Red Sea,” U.S. Naval Institute News, 19 February 2024, and Amila Prasanga, “Escalation beneath the Waves: The Looming Threat of Houthi UUVs in the Red Sea,” Center for International Maritime Security, 8 May 2024.

[44] Brendan Murray and Alex Longley, “Shipping Giant MSC Says It Will Avoid Red Sea for Now,” Bloomberg News, 21 January 2025.

[45] Alison Bath, “Navy Fired More than 200 Missiles to Fight off Red Sea Shipping Attacks, Admiral Says,” Stars and Stripes, 15 January 2025.

[46] “HMS Richmond Takes over from HMS Diamond to Protect Shipping in the Red Sea,” Royal Navy News, 6 February 2024; and Thomas Newdick, “French Frigate Captain Describes Frenetic Red Sea Combat,” War Zone, 6 April 2024.

[47] Tamar Michaelis and Oren Liebermann, “Israel Fails to Intercept Houthi Missile Targeting Its Main Airport, Showing the Limits of U.S. Efforts to Weaken the Group,” CNN, 4 May 2025.

[48] “Defense Officials Testify on Joint Force Readiness.”

[49] Stephen Losey, “Anduril Unveils Modular, High-Production Barracuda Cruise Missiles,” Defense News, 16 September 2024; Noah Robertson, “Anduril Debuts Bolt, Loitering Munition on Contract with Marine Corps,” Defense News, 10 October 2024; and Danny Chrichton, host, Riskgaming, podcast, “The Future of Defense Manufacturing with Anduril CEO Brian Schimpf,” Lux Capital, 15 November 2024.

[50] Veronika Melkozerova, “Ukraine’s Long-range Neptune Cruise Missile Is a Potential Trump Card,” Politico, 20 March 2025.

[51] Amir Daftari, “Iran Unveils New Missile Capable of Striking US Targets,” Newsweek, 5 May 2025.

[52] Brandon J. Weichert, The Shadow War: Iran’s Quest for Supremacy (New York: Republic, 2023); Gabriel G. Tabarani, How Iran Plans to Fight America and Dominate the Middle East (Bloomington, IN: Authorhouse, 2008); and Eyal Zamir, Countering Iran’s Regional Strategy: A Long-Term, Comprehensive Approach (Lanham, MD: Rowman and Littlefield, 2023).

[53] Sam McNeil, “Hypersonic Missiles Are Stirring Fear in the Iran-Israel Conflict. Here’s Why,” Washington Times, 18 June 2025.

[54] Jen Judson, “Aerojet’s President Talks New Approach to Making Rocket Motors,” Defense News, 16 April 2025.

[55] Wasser and Sheers, From Production Lines to Front Lines.

[56] “Defense Officials Testify on Joint Force Readiness.”

[57] Robert O. Work and Tara Murphy Dougherty, 2025 National Security Scorecard: Defense Acquisition Critical Capabilities (Arlington, VA: Govini, 2025).

[58] Popescu, “Adapting U.S. Defense Strategy to Great-Power Competition.”

[59] 21st Century Industrial Base for National Defense, 2–9.

[60] Jake Epstein, “Army Secretary Says U.S. Can’t Keep Pumping Money into Expensive Weapons that Can Be Taken out by an $800 Russian Drone,” Business Insider, 7 May 2025; Jake Epstein, “The U.S. Navy’s Overreliance on Top Missile Interceptors is ‘Unsustainable’ in More Intense Fights, Top Admiral Warns,” Business Insider, 15 July 2025; and ‘ “Alarming Depletion’: U.S. Patriot Interceptor Arsenal Falls to Just 25 Percent of Minimum Requirements,” Military Watch, 8 July 2025.

[61] Charles E. Kirkpatrick, An Unknown Future and a Doubtful Present: Writing the Victory Plan of 1941 (Washington, DC: U.S. Army Center of Military History, 1990).

[62] Pete Modigliani and Matt MacGregor, “Speed Is the Essence of War,” Defense Tech and Acquisition, 7 May 2025.